Automatic Packaging Line for Pre-made Bags

Fully automated with pre-made bag packing line – fast filling, precise packaging, productivity 1,800 bags/hour. Ideal solution for modern factories!

- Hotline: 0965 800 166

In the era of industry 4.0, factories are gradually turning to automation to improve productivity, optimize costs and ensure consistent product quality. Standing out in this trend is the automatic packaging line for pre-made bags , with a capacity of up to 1,800 bags/hour , integrating many modern technologies, bringing outstanding efficiency to businesses in the food, beverage, cosmetics and pharmaceutical industries.

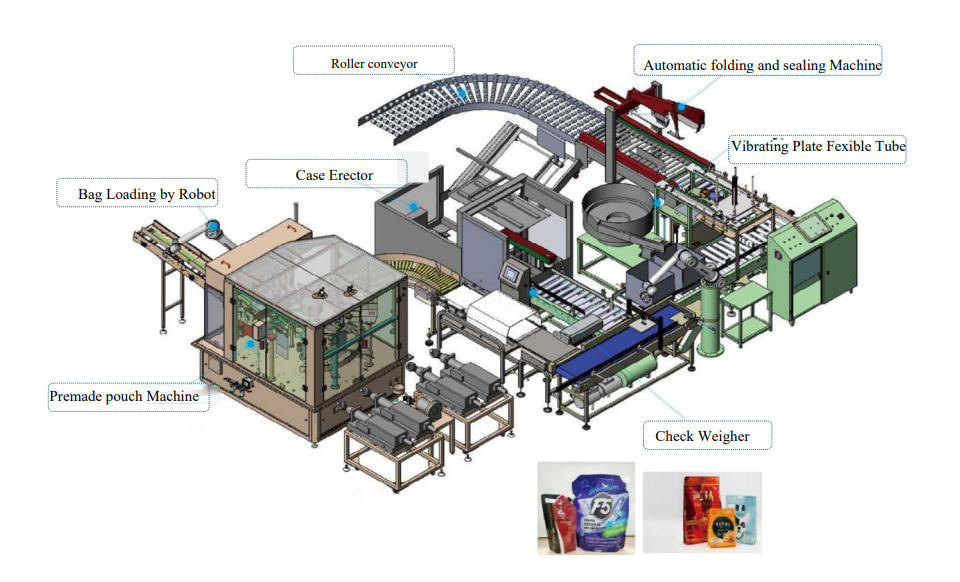

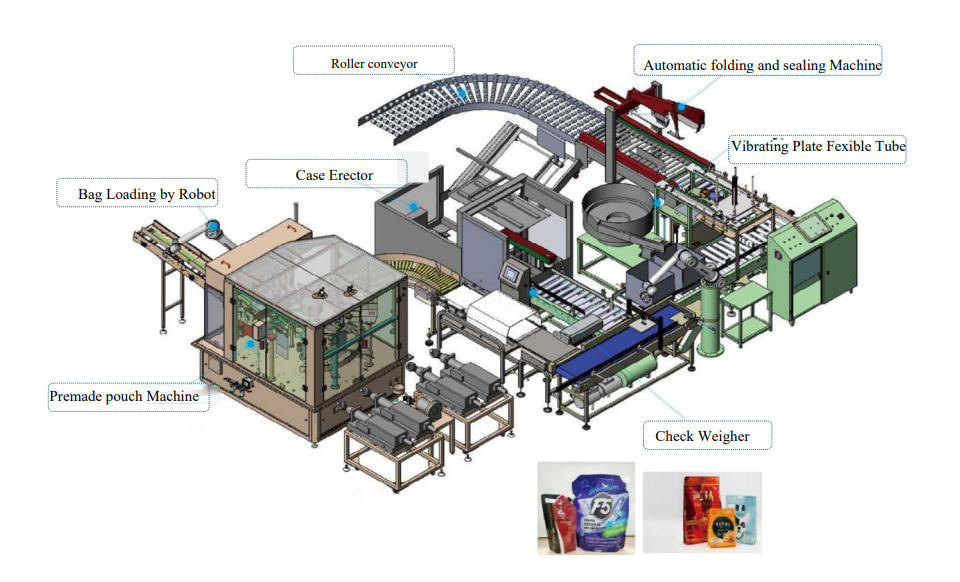

1. Overview of Pre-made Bag Filling and Packaging Line

The line is specially designed to fill and pack liquid or viscous products into pre-formed stand-up pouches, spout pouches or zipper pouches . The process is fully automatic, ensuring high speed and accuracy.

2. Main Stages in the Production Line

- Automatic double quantitative filling: The system uses 2 filling heads that can be flexibly set for each type of product, ensuring fast and accurate filling speed.

- Robot bag filling: Pre-made bags are picked up by robots and brought to the filling area, helping to reduce labor and optimize operations.

- 90° Flexible Transport: The conveyor system is designed to change the transport direction flexibly, saving installation space.

- Large bag inspection and automatic removal: Non-standard bags are automatically removed from the line without manual intervention.

- Packing with collaborative robots (cobots): Finished products are placed in cartons by robots, packed accurately and quickly.

- Flexible hose countdown with vibrating disc: Smart flexible hose feeding system with vibrating disc ensures continuous supply, without line interruption.

- Automatic folding and sealing: The bag mouth is folded and heat-sealed to create a tight seal, protecting product quality during storage and transportation.

- Finished product transportation: The final product is taken to the storage or delivery area by conveyor, ready for the next stage.

See also: Smart packaging system for puffed food

3. Outstanding Advantages of the Chain

- Full automation: Reduces dependence on manual labor, increases stability of the production line.

- High speed, time saving: Capacity up to 1,800 bags/hour , meeting large-scale production needs.

- High precision and safety: Integrated sensors and intelligent inspection systems.

- Flexible for each type of bag and product: Easily adjust the quantity and packaging style.

- Compact design, suitable for Vietnamese factory space.

4. Practical Application

The line is suitable for many industries:

- Food and drinks: Fruit juice, nut milk, soup, sauce, fish sauce…

- Cosmetics: Shampoo, hand soap, laundry detergent…

- Medical – pharmaceutical: Antiseptic gel, syrup, medical solution…

With the ability to integrate robots and smart technology, the automatic packaging line for pre-made bags with a capacity of 1,800 bags/hour is the optimal choice to modernize production, increase competitiveness and save on labor costs. Enterprises investing in this solution will quickly reap outstanding results in both product quality and operational efficiency .

Are you looking for a high-capacity, cost-effective and efficient automatic packaging line for pre-made bags ? Do not hesitate to contact us for:

- Detailed advice on the most suitable solution for your size and industry

- Competitive quotes and prompt technical support

- Dedicated installation, training and maintenance support

Contact us today to upgrade your production and get ahead of the automation trend!