Smart Packaging System For Puffed Food

Smart packaging system for puffed food with a capacity of 7,200 bags/hour, automatically integrated from feeding, weighing, packing to nitrogen injection and sealing – the optimal solution for modern production lines.

- Hotline: 0965 800 166

In the context of the increasingly developing food industry, the application of smart packaging systems not only helps increase productivity but also ensures quality and consistency for each product. Especially for puffed food products such as potato chips, snacks, popcorn, etc. , the need for an automatic, precise and high-speed packaging line is becoming an inevitable trend.

Capacity 7,200 Bags/Hour – Optimize Production Efficiency

This smart packaging system has a capacity of up to 7,200 bags/hour , suitable for medium and large-scale factories. With a scientific design and close combination of automatic equipment, the system helps shorten packaging time , reduce labor costs and increase stability in production .

Closed Packaging Process

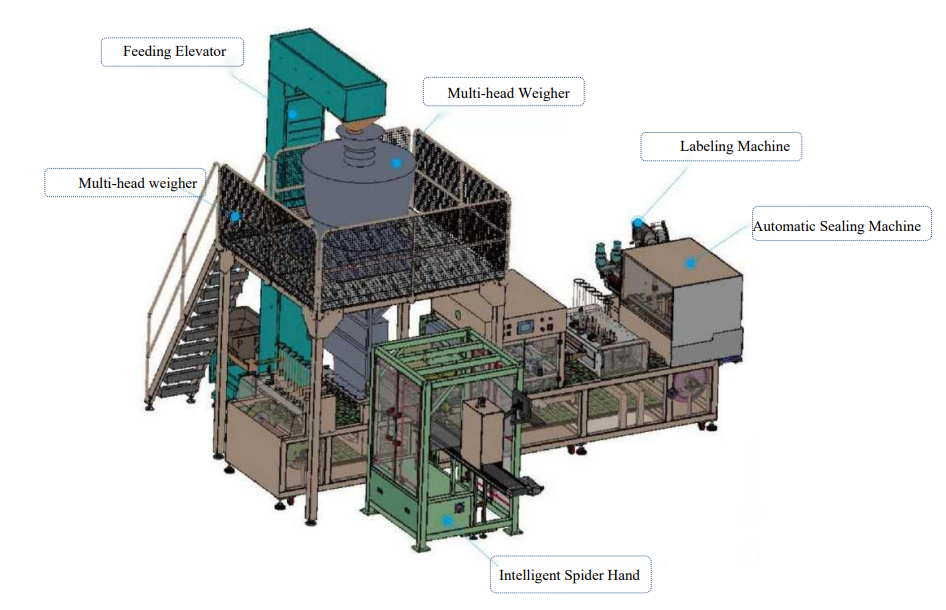

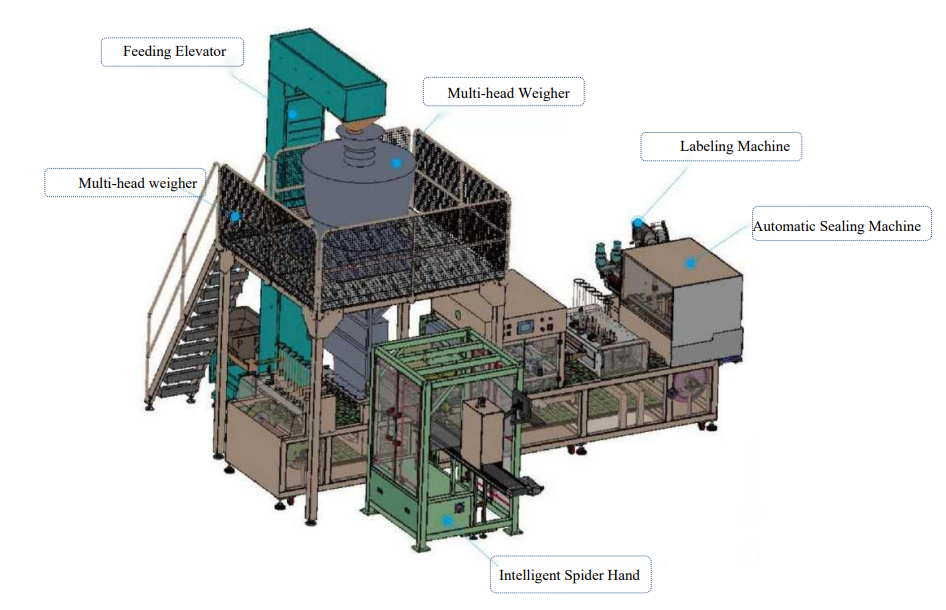

The packaging line for puffed food includes many continuous stages, operating fully automatically:

- Vibrating feed elevator : Feeds raw materials such as potato chips to the weighing machine.

- 14-head weigher : Ensures accurate weight of each package, reduces errors and loss.

- Automatic vibration unloading (1/6) : Smoothly insert products into each package.

- Automatic cartoning : Finished products are packed precisely into cartons.

- Smart Spider Robot : Uses artificial intelligence and machine vision systems to accurately locate and place boxes on the conveyor.

- Air cylinder : Push the barrel into the correct position, ready for the next steps.

- Automatic film pulling, sealing and nitrogen injection : Preserve products for a long time, keeping the crispness and flavor intact.

- Capping – Finishing line : Finishing the product to prepare for shipping.

Learn more about ETEK’s other packaging machine processes HERE

Outstanding Benefits of the System

- Increase production efficiency: Ensure high speed and accuracy.

- Reduced manpower: Fully automatic operation, requiring only a few supervisors.

- Long term cost savings: Less maintenance, reduced material loss.

- Ensure food hygiene and safety: Closed packaging process to avoid contamination.

- Easy integration with smart management systems (SCADA/IoT): Remote monitoring, real-time reporting.

Diverse Applications in the Food Industry

The system is especially suitable for manufacturing plants:

- Snacks, chips

- Popcorn, roasted kernels

- Rice crackers, dried seaweed

- And other light dry foods

Optimize your production line today with smart packaging systems – Advanced automation solutions for the modern food industry!