Tube Filling and Sealing System for 3-Pack

Discover the tube filling and sealing packaging system for 3-product packs with a capacity of 1,800 bags/hour – a modern automation solution that optimizes productivity, accuracy and product quality in the food, pharmaceutical and cosmetic industries.

- Hotline: 0965 800 166

1. Introducing Tube Filling and Sealing System for 3-Pack

In the modern manufacturing industry, the requirements for speed, accuracy and consistency in packaging are becoming increasingly stringent. To meet that need, the packaging system for tube filling and sealing sealing for 3-pack was born as a comprehensive solution, helping businesses optimize processes, reduce costs and improve the quality of output products.

This system is specially designed for powder, paste or multi-component mixture products. With a capacity of up to 1,800 bags/hour , the machine is suitable for medium and large-scale factories, meeting large output while ensuring stability and uniformity for each product bag.

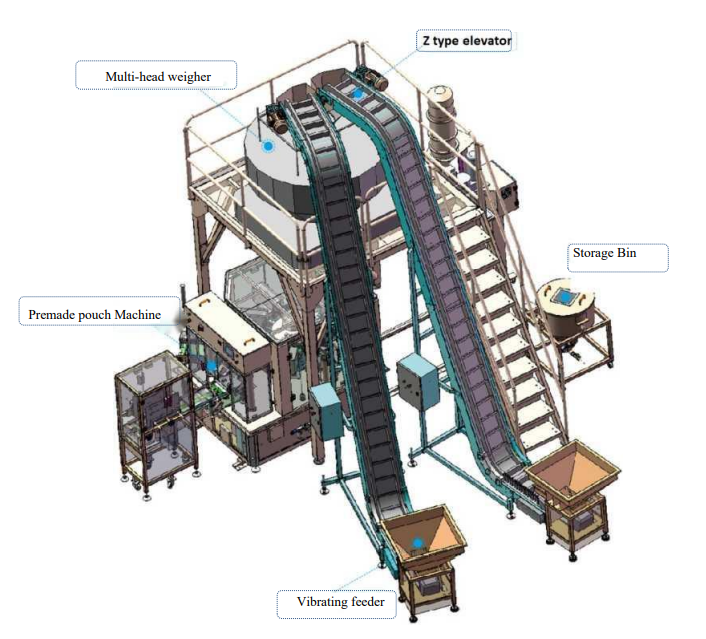

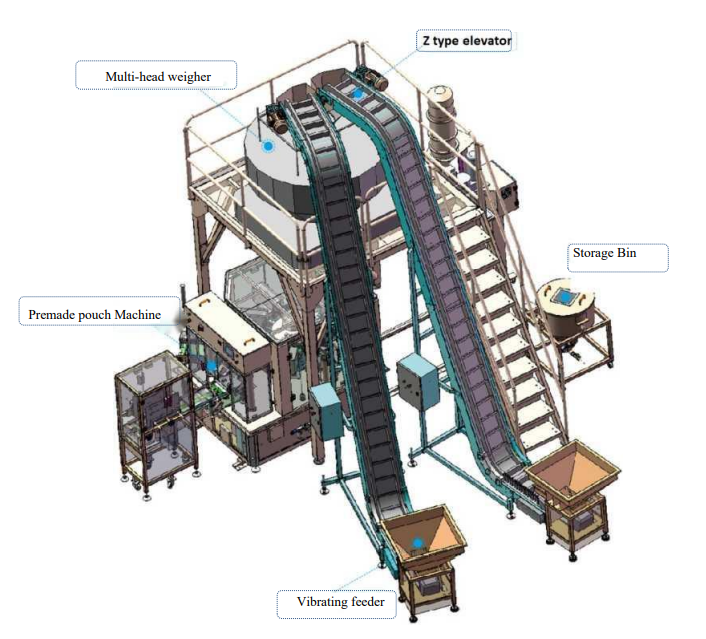

2. System operation process

Step 1: Mix and measure ingredients

- The system is capable of mixing three different products simultaneously , through separate hoppers and intelligent controls.

- Integrated automatic weighing scale ensures each ingredient is accurately dispensed at the predetermined ratio.

Step 2: Pouring raw materials

- After mixing, the raw materials are fed into the filling machine by a pump or screw system depending on the nature (powder, paste).

- Flexible, highly precise filling mechanism, can adjust filling volume for each type of product.

Step 3: Pack into pre-made bags

- The system uses pre-prepared packaging bags (standing, flat, etc.), saving time in creating bags.

- The bag is placed in a predetermined position, the filling process is completely automatic, ensuring a closed and hygienic environment.

Step 4: Weld the bag and export the finished product

- After the bag is fully filled, the edges will be sealed using high frequency heat technology or conventional heat welding.

- The welded product is pushed to the output conveyor, ready for packing or shipping.

Refer to the process of the FX120 Aseptic Filling Machine: FX120 Aseptic Filling Machine | TPA

3. Outstanding advantages of the system

- Fully automated, minimizing operating labor.

- Precise dispensing, no waste of materials, suitable for products requiring strict quantification.

- Using pre-made bags saves production time and is flexible in design.

- High performance, well meets mass production needs, increases productivity many times compared to manual.

- Ensure food hygiene and safety, closed system, easy to clean and maintain.

4. Practical application

The 3-product tube filling and sealing packaging system is widely applied in many fields:

- Food industry: Nutritional powder, cereal, milk powder, mixed spices.

- Pharmaceutical industry: Powdered medicine packages, powdered oriental herbal medicine.

- Cosmetics industry: Facial cleanser, powder mask, cream mixed according to formula.

- Light chemical industry: Washing powder, powder detergent, specialized cleaning powder.

5. Why should businesses invest in this system?

- Long-term cost savings: Reduced staffing, reduced product defects, increased packaging speed.

- Improve quality: Precise mixing ratio, sturdy bag welding, beautiful design.

- Space optimization: Compact design, easy to integrate into existing production lines.

- Increase competitiveness: Meet the strict requirements of domestic and export markets.

You may be interested in: Fully Automatic Tube Filling and Sealing Machine

The 3-product tube filling and sealing packaging system is one of the most modern and effective solutions today, helping businesses in the food, pharmaceutical, cosmetic and chemical production sectors to improve productivity, ensure quality and optimize operating processes. With a capacity of 1,800 bags/hour , flexible mixing capabilities and fully automatic operation, this system is a powerful assistant for every factory aiming for automation and sustainable development.