Automatic Tube Filling and Sealing Machine

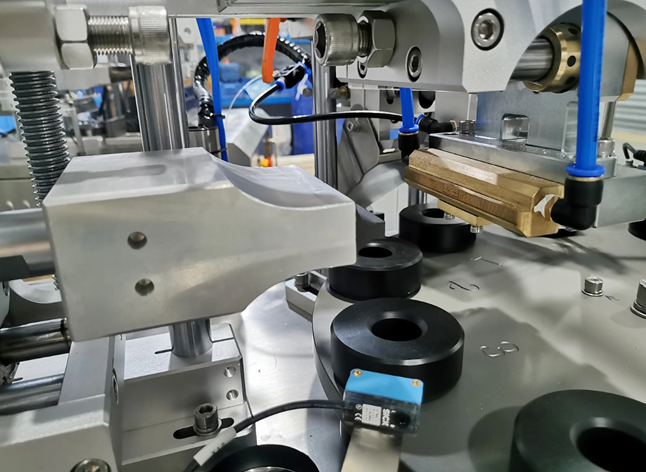

The equipment has a high degree of automation, using internal heating method, using air heater to blow hot air into the inner surface of the tube to melt the plastic layer then stamp and print the batch number.

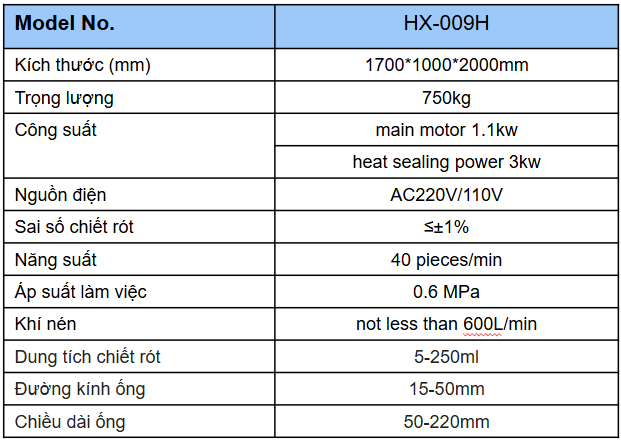

- Capacity: 40 products/minute

- Filling capacity: 5-250ml

- Pipe diameter: 15-50mm

- Tube height: 50-220mm

- Hotline: 0965 800 166

Fully automatic tube filling and sealing machine is a modernly designed device, integrating many smart features, suitable for industries such as food, cosmetics, medicine, chemicals and many other industrial fields.

1. Modern design, highly automated

The filling machine stands out with its shiny, durable and easy-to-clean stainless steel design, ensuring GMP standards in production. The device has a high level of automation , helping businesses optimize the production process effectively.

The machine uses the internal heating method with hot air , blowing air into the inside of the tube to melt the plastic layer, then seals and prints the batch number – ensuring a strong, aesthetic and precise weld.

2. Smart automatic operation process

The filling machine performs the tube filling and sealing process fully automatically through 12 clear steps :

- Insert tube into auto feeder

- Automatically detect and locate color points

- Load tubes into workstation

- Cylinder accurately positions the tube

- Fix the tube direction according to the marker

- Cylinder filling and preparation for filling

- Pouring raw materials into tubes

- Cylinder head sealing press

- Sealing by ultrasonic technology

- Cut off the excess

- Push the finished product out

- Tube slides down to finished product tray

3. Technical parameters

4. Flexible application in many industries

Filling machines are widely used in the following fields:

- Food and beverage : filling cream, jam, sauce, thick spices…

- Cosmetics : moisturizer, cleanser, sunscreen…

- Medical, pharmaceutical : ointments, gels, topical creams…

- Chemicals : glue, detergent, dye…

- Machinery and hardware : lubricants, specialized adhesives…

5. Outstanding benefits when investing in tube filling and sealing machines

- Optimized productivity : up to 40 products/minute, significantly increasing production speed.

- Reduce labor costs : automatic operation, only need 1 supervisor.

- Ensure high accuracy : filling error ≤±1% , helping to save materials.

- Consistent product quality : thanks to ultrasonic welding technology and modern quantitative control system.

- Easy to operate and maintain : intuitive touch control panel, sturdy machine structure, easy to clean.

Automatic tube filling and sealing machine is the optimal choice for businesses that want to increase production efficiency, improve product quality and reduce operating costs. With modern design, high precision and multi-industry application, this equipment is a sustainable investment solution for the future.