Weighing and packing line

Capacity 800-1000 barrels/hour

The automatic weighing and packing line is an integrated system of mechanics, robots and image processing technology to pack products into cartons quickly, accurately and safely. The system is suitable for fast-moving consumer goods (FMCG), beverage, food, pharmaceutical and many other manufacturing fields.

- Hotline: 0965 800 166

In the context of modern industrial production, weighing and packing lines play an important role in optimizing performance and ensuring product quality. With a capacity of 800-1000 cartons/hour , this line helps businesses shorten processing time, reduce labor and improve accuracy in each packaging stage.

1. Overview of weighing and packing line

The automatic weighing and packing line is an integrated system of mechanics, robots and image processing technology to pack products into cartons quickly, accurately and safely. The system is suitable for fast-moving consumer goods (FMCG), beverage, food, pharmaceutical and many other manufacturing fields.

2. Outstanding capacity: 800–1000 barrels/hour

With a processing speed of up to 1000 cartons per hour, the cartoning line helps businesses increase productivity while ensuring product quality, minimizing risks caused by manual operations.

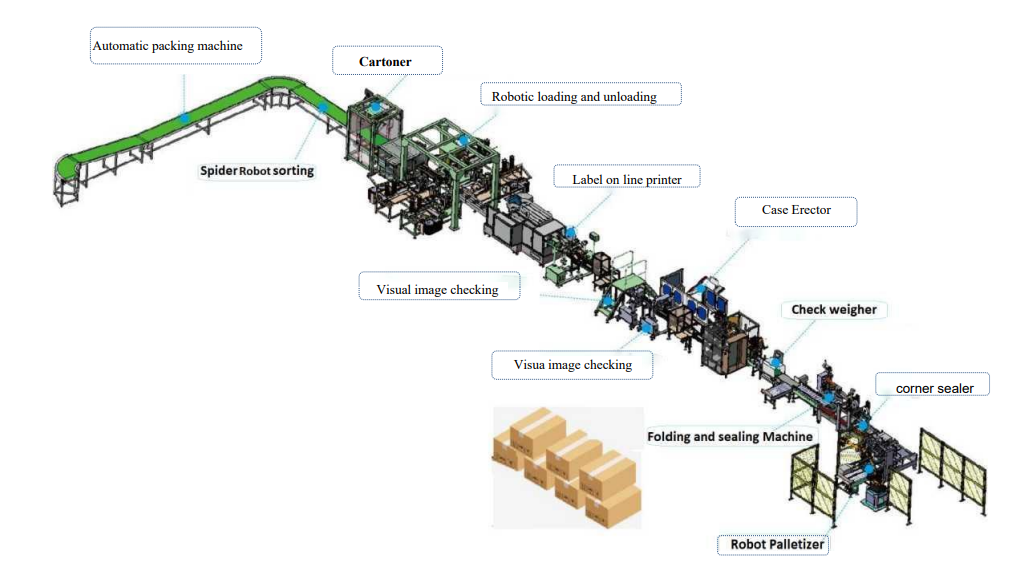

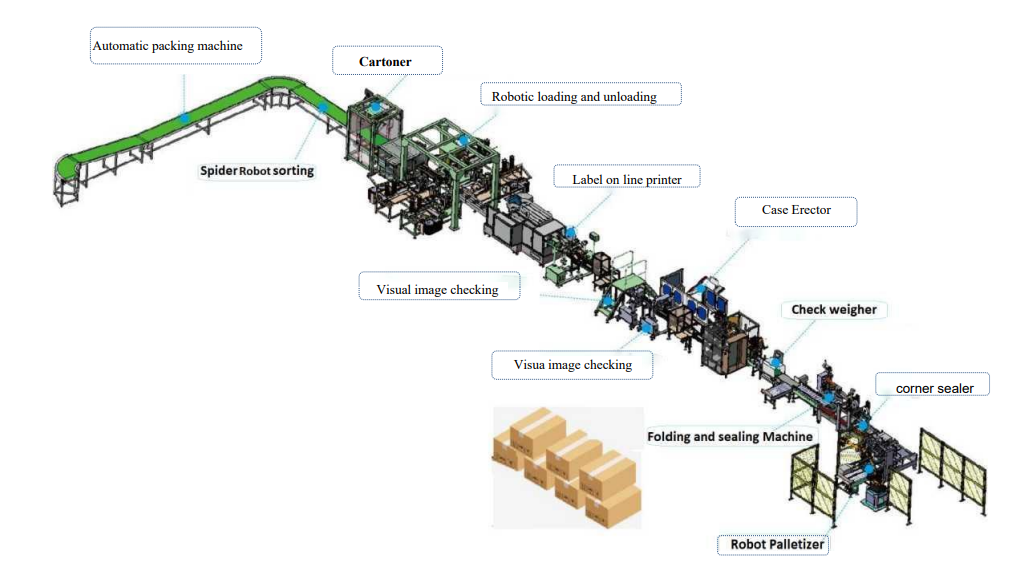

3. Detailed operating procedures

Below is the standard operating procedure of the automatic cartoning line :

- Take the product off the assembly line.

- Transfer via conveyor to inspection area.

- Preliminary manual check.

- Product sorting by spider robot.

- Scan the code and bag the product.

- Automatic bag loading and unloading by robot.

- Automatic paper tray loading into bin.

- Attach color labels and anti-removal labels to cartons.

- Check images with AI camera system, eliminate defective products.

- Automatic label printing with industrial printers.

- Visually check the label again, remove defective labels.

- Remove packaging and tamper evident label as required.

- Place the bottom paper tray in the bin.

- Pack products accurately according to quantity.

- Place the paper tray on top.

- Weigh the crates and discard the incorrect weight crates.

- Print – label in real time.

- Fold and seal the carton, attach anti-removal label.

- Label the corners and proceed to stack.

- Manually pull the bin out of the stack when full.

You may be interested in: Automatic robot system for packing liquid bag products

4. Outstanding advantages of automatic carton packing line

- Complete automation from inspection, packaging, labeling to sealing.

- Reduce staff, optimize operating costs.

- High precision, control of product weight and appearance.

- Integrating modern AI and robotics technology.

- Suitable for a variety of products and box sizes.

5. Practical application

This line is commonly used in large factories such as:

- Beverage and packaged food factory

- Agricultural export enterprise

- Consumer goods factory

- Logistics distribution lines require mass packaging

The 800–1000 cartons/hour weighing and packing line is the ideal solution to improve efficiency and product quality in modern factories. Investing in this system not only brings economic benefits but also helps businesses meet the strict standards of domestic and international markets.

Are you looking for an automatic weighing and packing line solution with optimal capacity for your factory? We provide design, installation and technology transfer solutions suitable for all practical production needs.

Hotline: 0965 800 166

Email: info@etek.com.vn

Website: etekpackmachine.com