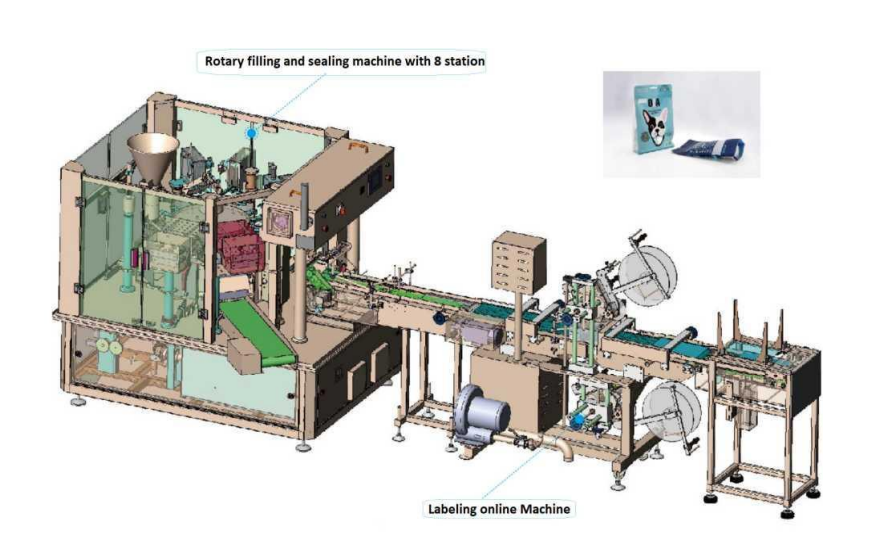

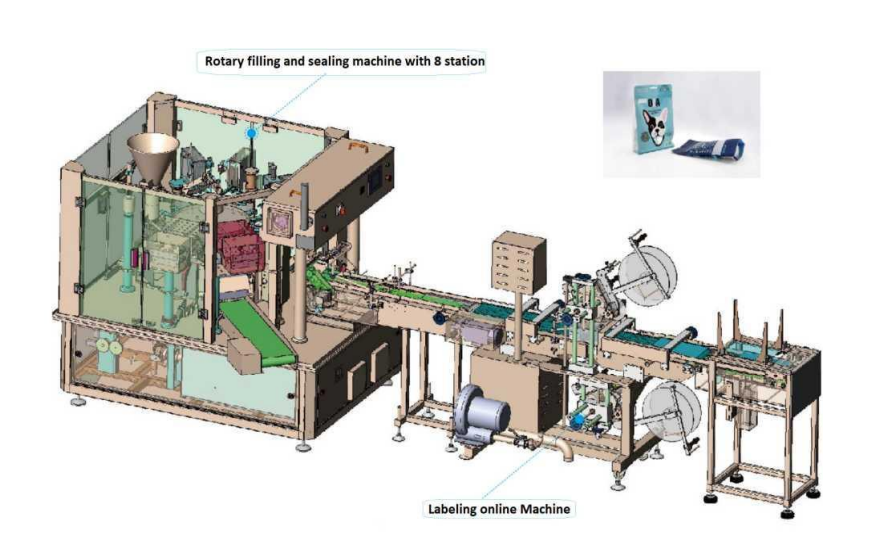

Tube filling and sealing packaging system with labeling

Discover the automatic tube filling and sealing system with labeling, capacity 1800 bags/hour – the optimal solution for pre-made bag production lines. Increase productivity, reduce costs, and enhance the professionalism of your products.

- Hotline: 0965 800 166

In the era of industry 4.0, automating the production line not only helps to improve productivity but also ensures consistent quality and optimizes costs. The tube filling and sealing packaging system with labeling is one of the advanced solutions, chosen by many manufacturing enterprises to optimize the process of packaging pre-made bags.

1. Introduction to tube labeling and filling packaging system

The system integrates many stages: from online labeling , filling raw materials , to tube welding and delivering finished products . All take place completely automatically, ensuring stable and consistent performance in each product bag.

- Capacity: 1800 bags/hour

- Packaging Type: Pre-made bags (doypack, stand-up pouch, zipper bag, etc.)

- Application: Suitable for food, cosmetics, chemicals, pharmaceuticals…

See details about tube filling and sealing machine products HERE

2. Automatic operating process

The system operates in the following order:

- Online labeling: Labels are printed and applied directly to the bag prior to filling.

- Filling: Raw materials are accurately measured and filled into bags.

- Sealing: The bag is securely sealed to ensure product hygiene and safety.

- Finished output: The finished bag is transferred to the next finishing or packaging conveyor.

3. Outstanding advantages of the system

- High automation: Reduce labor, increase production efficiency.

- Accurate and uniform: Precise dosing system, helps the product to be uniform.

- Cost savings: Reduce loss of raw materials, time and manpower.

- Flexible customization: Can be adjusted to fit a variety of bag types and filling capacities.

- Increase product professionalism: Precisely applied labels help increase brand recognition.

4. Practical applications

Tube filling and labeling packaging systems are widely used in manufacturing plants:

- Juice, nut milk, instant coffee

- Cosmetics in cream, gel, solution form

- Liquid seasoning, fish sauce, soy sauce

- Liquid detergents and cosmetics

5. Why should you invest in this system?

- Optimize production process

- Increase productivity while ensuring quality

- Meet market demands for beautiful packaging and professional labeling

- Increase competitiveness for businesses

If you are looking for a modern, highly automated packaging solution for bag products, please contact us immediately for advice on the system that best suits the scale and product characteristics of your business.

👉 Discover smart, highly efficient packaging machine solutions at:

🔗https://etekpackmachine.com/en/collection/automatic-packaging-machine