Smart Packaging System

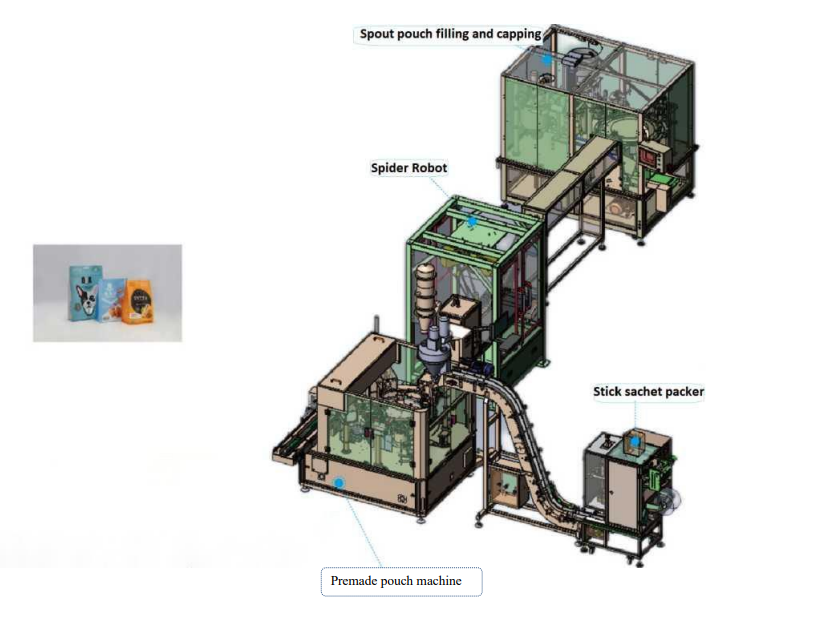

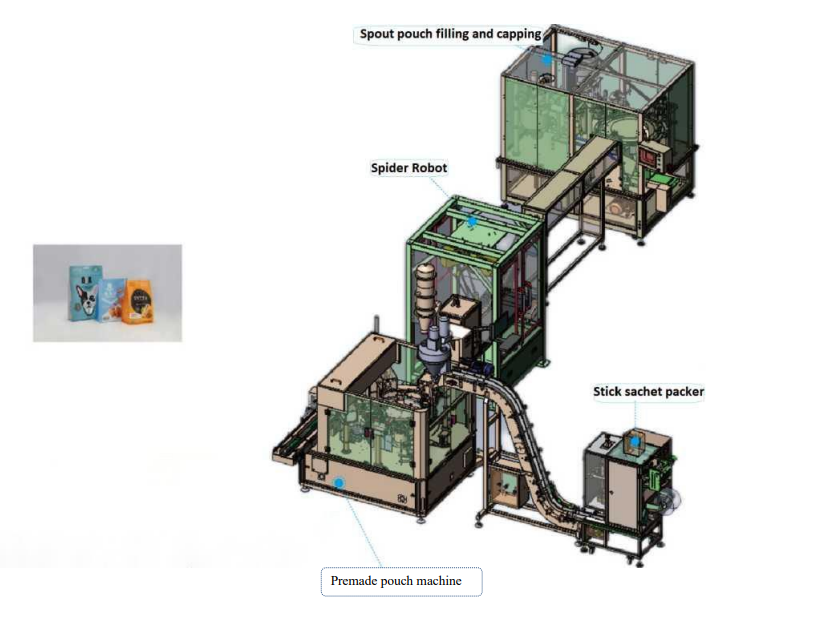

Discover the smart automatic packaging system with a capacity of 1800 bags/hour – integrating stick packaging machine, filling machine, sorting robot, automatic capping machine. The optimal solution for modern factories.

- Hotline: 0965 800 166

In the era of industry 4.0, the application of smart packaging systems not only helps businesses improve production efficiency but also ensures product quality and optimizes labor costs. One of the outstanding solutions today is the automatic packaging line with a capacity of 1800 bags/hour , designed to integrate many modern technologies.

1. Overview of Smart Packaging System

This packaging line is built on a highly automated platform, combining precision mechanics, PLC control and industrial robots. The system includes continuous stages from filling, sealing, sorting to packaging finished products:

- Single-lane stick packing machine : Specialized equipment for forming and sealing powder, liquid or gel products in stick bags. Stable speed, high precision, suitable for pharmaceutical, cosmetic or functional food industries.

- Fixed stop conveyor : Allows products to pause precisely at each position, supporting synchronized filling and packaging operations, avoiding vibrations that affect product quality.

- Rotary filling and sealing machine : Applied in processing pre-formed bags (bags + powder bags), the equipment operates continuously according to the rotating mechanism, ensuring high speed while still being accurate to each ml of liquid or each gram of powder.

- Visual robot + material sorting spider robot : Integrating visual camera technology and AI, helping to detect product defects, quickly classify by model or color. Spider robot ensures flexible, high-speed operation without affecting the product.

- Automatic jar sealing + capping machine : For bottled or plastic jar products. The device helps to center, close the cap accurately and tighten according to standards, ensuring tightness and hygiene.

2. Outstanding Advantages

- 100% automation of packaging process from raw materials to finished products.

- Stable capacity of 1800 bags/hour , well meeting the needs of large-scale production.

- Save manpower, reduce errors due to manual operations.

- Multi-purpose: Can pack many types of materials (powder, liquid, stick, plastic bottle…).

- Integrating intelligent robots helps improve accuracy and control output quality.

3. Practical Applications

This system is suitable for industries:

- Food and beverage: Packaging milk powder, functional foods, jelly, nutritional water.

- Pharmaceuticals: Powder, liquid, injection solution.

- Cosmetics: Gel, cream, serum.

- Other industries: Washing powder, laundry tablets, industrial additives…

Investing in a smart packaging line with a capacity of 1,800 bags/hour is not only a step forward in technology but also a long-term strategy to increase the competitiveness of the business. This system will help the business ensure speed – accuracy – stability – savings, while significantly improving the operational efficiency of the entire factory.

Are you looking for an efficient, cost-effective and modern automated packaging solution? Let us accompany your business in upgrading your production line, optimizing performance and ensuring product quality.

We provide:

- Consulting on packaging line design on request.

- Providing stick packaging machines, filling and sealing machines, sorting robots, automatic capping machines…

- Installation, maintenance, technology transfer on site.

See also:

👉 Contact us today for advice on solutions that suit your business size and budget!

Sign up to receive a free quote and a live demo of the system at the factory.