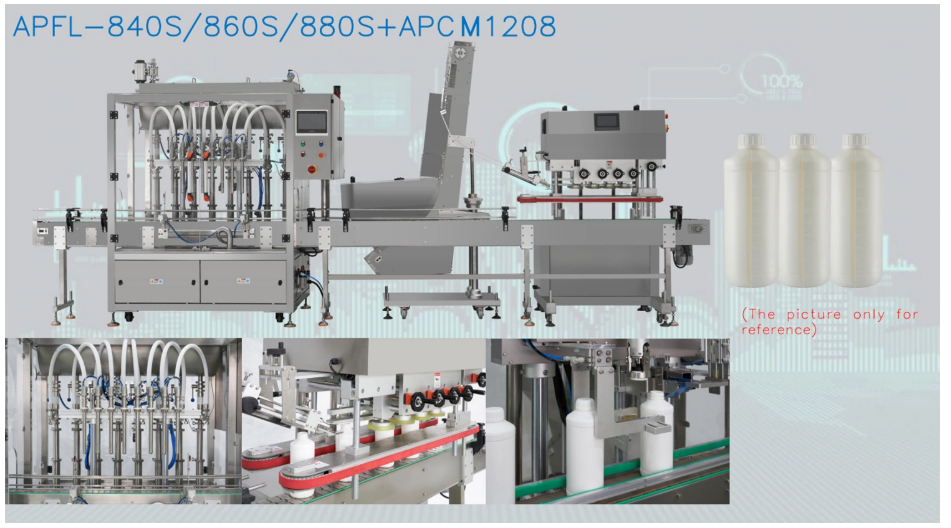

Automatic Servo Piston Filling Machine

Suitable for filling low viscosity and medium viscosity liquid. Widely used in chemical, medicine, pesticide, cosmetics, food or other fields.

Used for many different bottle types without changing machine parts

Filling capacity: 100ml-20L

Filling error: ± 0.5%

- Hotline: 0965 800 166

Optimizing processes, improving productivity and ensuring product quality are key factors leading to success. Especially in the liquid manufacturing industry, filling machines play an extremely important role. With strict requirements on accuracy, speed and adaptability to a variety of products, the Servo Controlled Piston Pump Automatic Filling Machine is emerging as a superior technological solution, meeting all needs from small to large-scale businesses.

1. General introduction of Servo Controlled Piston Pump Automatic Filling Machine

The servo-controlled piston pump automatic filling machine is a modern equipment, specially designed for filling low viscosity and medium viscosity liquids. The highlight of this machine line lies in the advanced servo motor-controlled piston pump technology, providing extremely high precision and stable, flexible operation.

2. Outstanding advantages

The core difference of this filling machine lies in the servo-controlled piston pump system. This technology brings many outstanding benefits:

- Absolute Accuracy: With a filling error of only ± 0.5%, the machine ensures the perfect amount of liquid is filled into each bottle, minimizing waste and ensuring product consistency.

- Flexible Capacity Adjustment: The machine is capable of filling with a very wide capacity range, from 100ml to 20L . This ability allows businesses to produce a variety of products, from small bottles to large cans, without having to change complex machine parts.

- Stable Operation and Low Maintenance: Servo motor provides precise and smooth control of the piston, making the machine operate smoothly, reducing vibration and wear of mechanical parts.

- Adaptability to a Wide Range of Liquids: Thanks to the special construction of the piston pump, the machine can effectively handle liquids of different viscosities, from drinking water, cooking oil to cosmetics, chemicals and pesticides.

3. Widely used in many industries

Servo filling machine with piston pump has high precision, good productivity, flexible application in:

- Food & Beverage : milk, soft drinks, cooking oil, sauces…

- Chemicals : solvents, detergents, paints…

- Medical & Pharmaceutical : liquid medicine, antiseptic…

- Cosmetics : shampoo, shower gel, lotion…

- Pesticides : plant protection products…

- Machinery : oil, lubricants…

The ability to fill different bottle shapes without changing machine parts helps businesses save significant time and costs in converting production lines.

4. Optimal operating procedures

The automatic filling machine operates in a closed, automatic and efficient process, ensuring the quality of the final product:

- Bottle level

- Lower the filling nozzle and fill the bottle (deep jet filling to avoid foaming)

- Anti-drip and spout lift mechanism

- Close the lid

- Move the product to another stage.

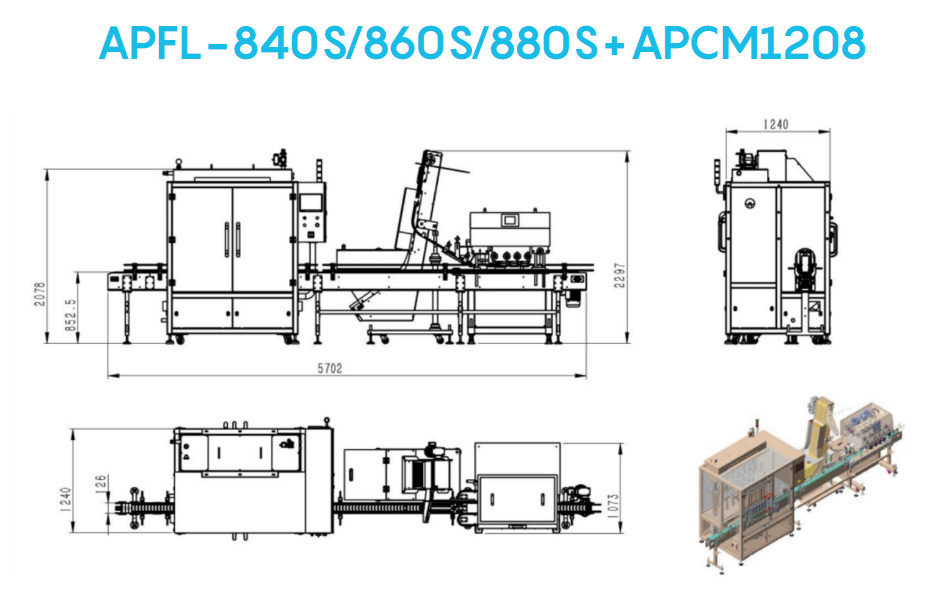

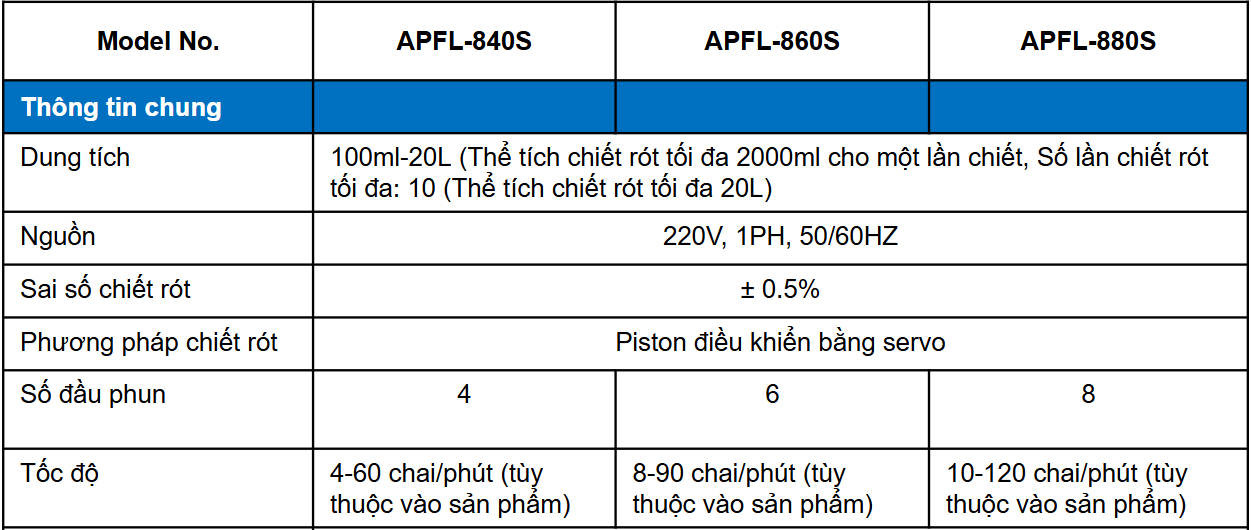

5. Detailed technical parameters of Servo Controlled Piston Pump Automatic Filling Machine

To meet diverse production requirements, Automatic Filling Machine has many different models, each model has optimal technical parameters:

6. Reasons to invest in automatic filling machine

- Increased productivity: Automation improves output to meet high demand.

- Quality assurance: High precision, consistent products.

- Cost savings: Reduce errors, waste of materials and labor.

- Safety and hygiene: Closed process, limited direct contact.

- Flexible use: Easy to adjust capacity and speed for many types of products.

The Servo Controlled Piston Pump Automatic Filling Machine is a breakthrough in filling technology, providing a comprehensive solution for liquid manufacturing enterprises. With the perfect combination of precision, speed and flexibility, this machine series not only helps optimize the production process but also contributes to improving product quality and enhancing competitiveness in the market.