Sauce production and packaging line

Discover the 3600 bag/hour sauce production and packaging line with automatic filling, sterilization, contamination testing and packaging systems – the optimal solution for modern food businesses.

- Hotline: 0965 800 166

In the food manufacturing industry, especially sauces, choosing a modern, automated packaging line is a decisive factor to improve productivity, ensure quality and food hygiene and safety. A sauce packaging line with a capacity of 3600 bags/hour is the ideal solution to help businesses meet the growing market demand with optimal efficiency.

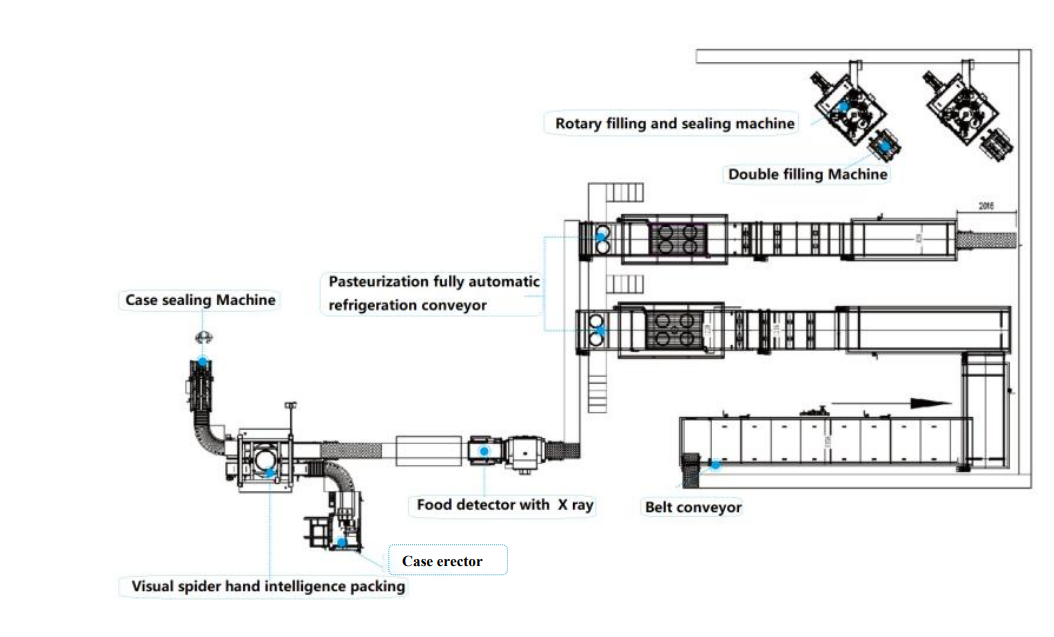

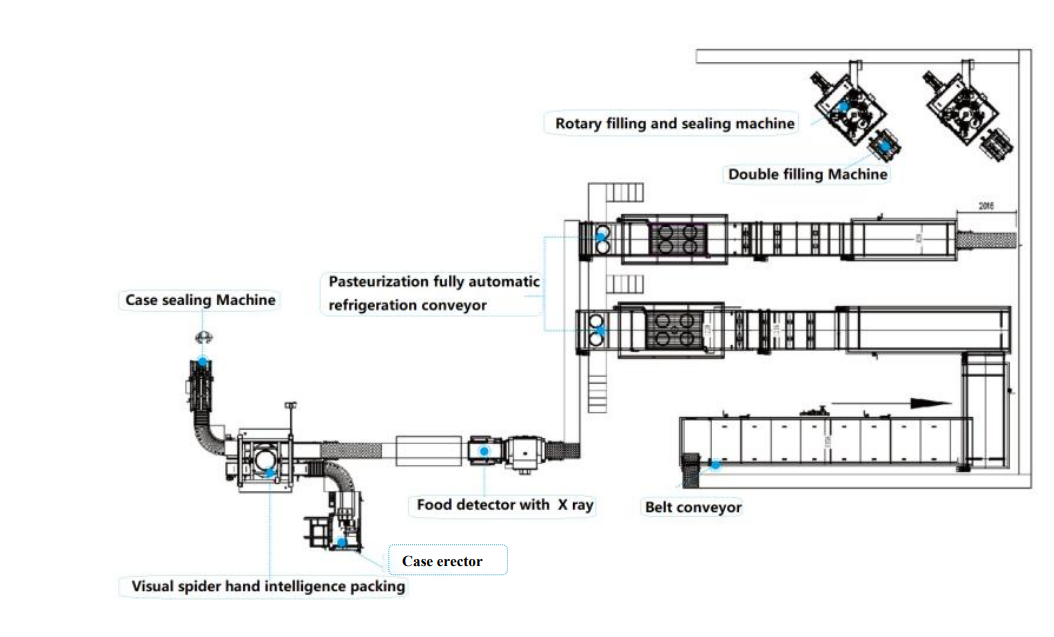

Overview of sauce packaging and production line

The sauce packaging line is designed in sync with the stages from filling to final packaging, ensuring fast operating speed, high accuracy, minimizing loss and pollution during the production process. The process includes the following main steps:

- Double quantitative filling machine: Precise filling equipment with 2 nozzles helps increase productivity, accurately control the amount of sauce per bag, ensuring consistent product quality.

- Rotary bag loading filling and packaging machine: Automatically open bag, fill and pack continuously, reduce waiting time and labor.

- Sterilization system: Eliminates bacteria and impurities, ensures product safety and hygiene, and prolongs shelf life.

- X-ray impurity removal machine: Check and remove unwanted metal foreign objects or impurities, enhancing product safety.

- Automatic bag unpacking: Supports efficient bag preparation process, reducing labor costs.

- Vision + Spider Manual Packaging: Complete packaging support with visual inspection, ensuring packaging quality.

- Automatic lid folding and sealing: Creates a sturdy, leak-proof finished product, protecting the product during transportation and storage.

- Output: Complete packaged product, ready for distribution and consumption.

Outstanding advantages of sauce packaging line

- High productivity: With a capacity of up to 3600 bags/hour , the line helps increase production efficiency, meeting even large orders.

- Accuracy and uniformity: The double quantitative filling machine helps to accurately measure each sauce bag, maintaining product quality.

- Food safety and hygiene: Sterilization system and X-ray machine to remove impurities help ensure strict hygiene standards.

- High automation: Minimizes human intervention, saves labor and reduces the risk of error.

- Sturdy, aesthetic packaging: Automatic lid folding and sealing system helps the product meet standards in both quality and appearance.

Applications and benefits of using sauce packaging line

This line is suitable for factories producing sauces, spices, chili sauce, ketchup, etc. that want to expand their scale, improve product quality and shorten production time. Applying an automatic line also helps businesses save operating costs and increase competitiveness in the market.