Packing and sealing system for popcorn

Automatic popcorn packing and sealing system – capacity 1800 bags/hour, integrated with oil filling, pouch & outer bag packaging. Effective solution for modern snack production.

- Hotline: 0965 800 166

In the food industry, especially the production of popcorn – a popular snack worldwide, packaging and sealing the product is an extremely important step. Not only does it help preserve the product, keep the delicious flavor and crispiness of the popcorn intact, but it also ensures food hygiene and safety and increases aesthetics, attracting consumers. To meet the increasing demand of the market, factories have been switching to using automatic packaging systems with large capacity. In particular, the packaging and sealing system for popcorn with a capacity of 1800 bags/hour is considered the optimal solution to help improve productivity, quality and production efficiency.

Professional automatic popcorn packaging process

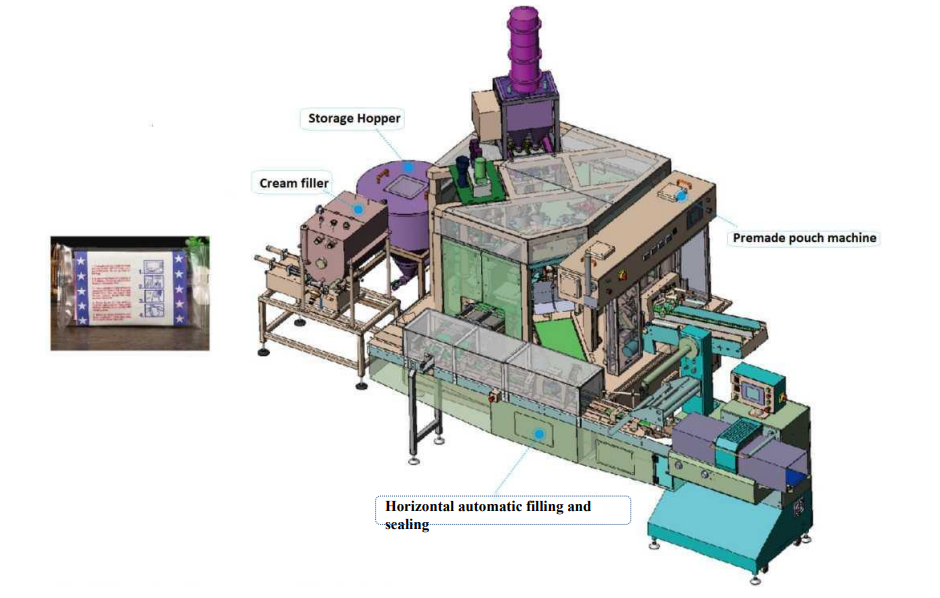

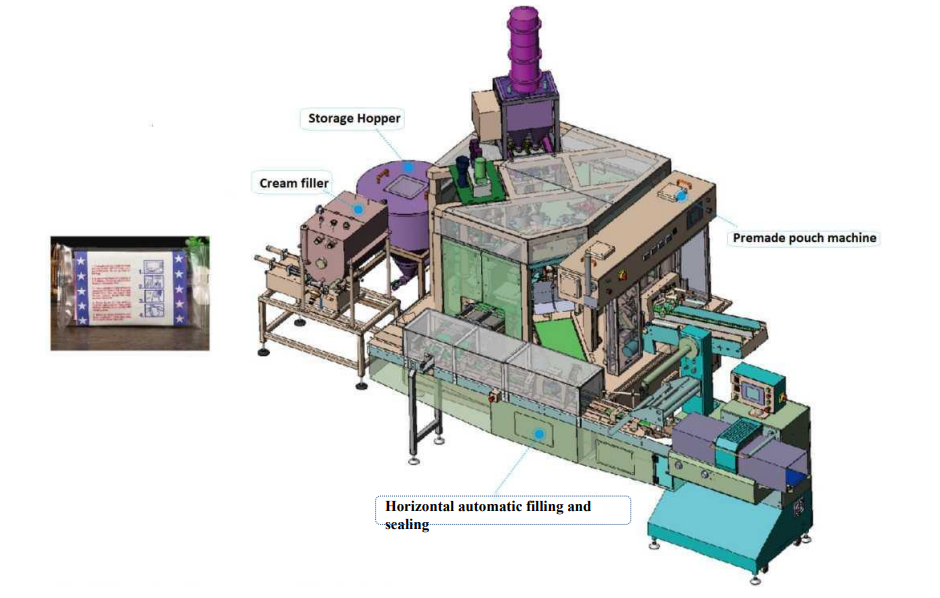

The popcorn packaging system is designed as a synchronous, continuous line consisting of many modern machines, ensuring that each step in the process is performed accurately, quickly and effectively:

1. Double quantitative filling machine for pressed oil

In the first step, the pressed oil – a key ingredient in creating the crispness and flavor of popcorn – is precisely dispensed using a double filling machine. This system saves raw materials, avoids waste and ensures the right oil ratio for each production batch.

2. Vacuum filling machine and quantitative cup filling machine

After preparing the raw materials, corn will be accurately quantitatively filled into cups or intermediate packaging through vacuum filling machines and quantitative cup filling machines. The vacuum method helps remove excess air, increase preservation capacity and limit oxidation, thereby extending the shelf life of the product.

3. Pre-made pouch filling and packaging machine

Pre-made pouch bags are a popular type of packaging today with the advantages of being compact, easy to transport and having good preservation ability. The automatic filling machine will put popcorn into the pouch bag quickly and accurately, while sealing the bag mouth, keeping the product fresh and delicious.

4. Horizontal automatic filling and packaging machine for outer bag

In the final step, the packed pouches are placed into the outer pouches by an automatic horizontal packaging machine. This step provides an additional layer of safety for the product during transportation, while also facilitating the packaging, distribution and display of the product on the market.

5. Production output

After being fully packaged and sealed, the product will be brought to the production output, ready for the final quality control steps before being released from the warehouse and distributed to consumers.

See more about the process of AUTOMATIC FOOD PACKING MACHINE WWP-A25

Outstanding benefits of using automatic packaging system for popcorn

Improve production productivity

With a capacity of up to 1800 bags/hour, the system significantly increases production output compared to manual or semi-automatic packaging. This is especially meaningful for factories with large production needs or wanting to expand their business scale.

Ensure product quality and consistency

The precise automatic dosing system ensures that the product has a uniform weight, avoiding deviations that cause imbalance and affect brand value. In addition, vacuum packaging and sealing technology helps preserve the flavor and crispiness of the popcorn.

Save costs and manpower

Fully automating the packaging process reduces labor requirements, reduces errors and material loss, and saves long-term operating costs. The plant can focus resources on more efficient production and marketing processes.

Ensure food safety and hygiene

The packaging process is completely operated by machinery, limiting direct contact with the product, thereby minimizing the risk of bacterial contamination and ensuring that the product meets strict hygiene standards of the food industry.

Easy to operate and maintain

The system is designed to be user-friendly, with an intuitive control interface, easy to install, operate and maintain, helping to reduce downtime and increase production efficiency.

Wide application and development potential

The automatic packaging and sealing system is suitable for many sizes of popcorn production enterprises from small to large, meeting the diverse and increasing production needs of the market. Investing in a modern packaging line not only helps to improve productivity but also builds a prestigious brand, increases competitiveness and expands export markets.

In addition to popcorn, the system can also be easily customized to package other snacks, dried foods or granular products, providing great flexibility for manufacturers.

Contact us now for advice and quotes on high quality, high capacity automatic packaging systems.