CoLOS Printer Control and Management Software

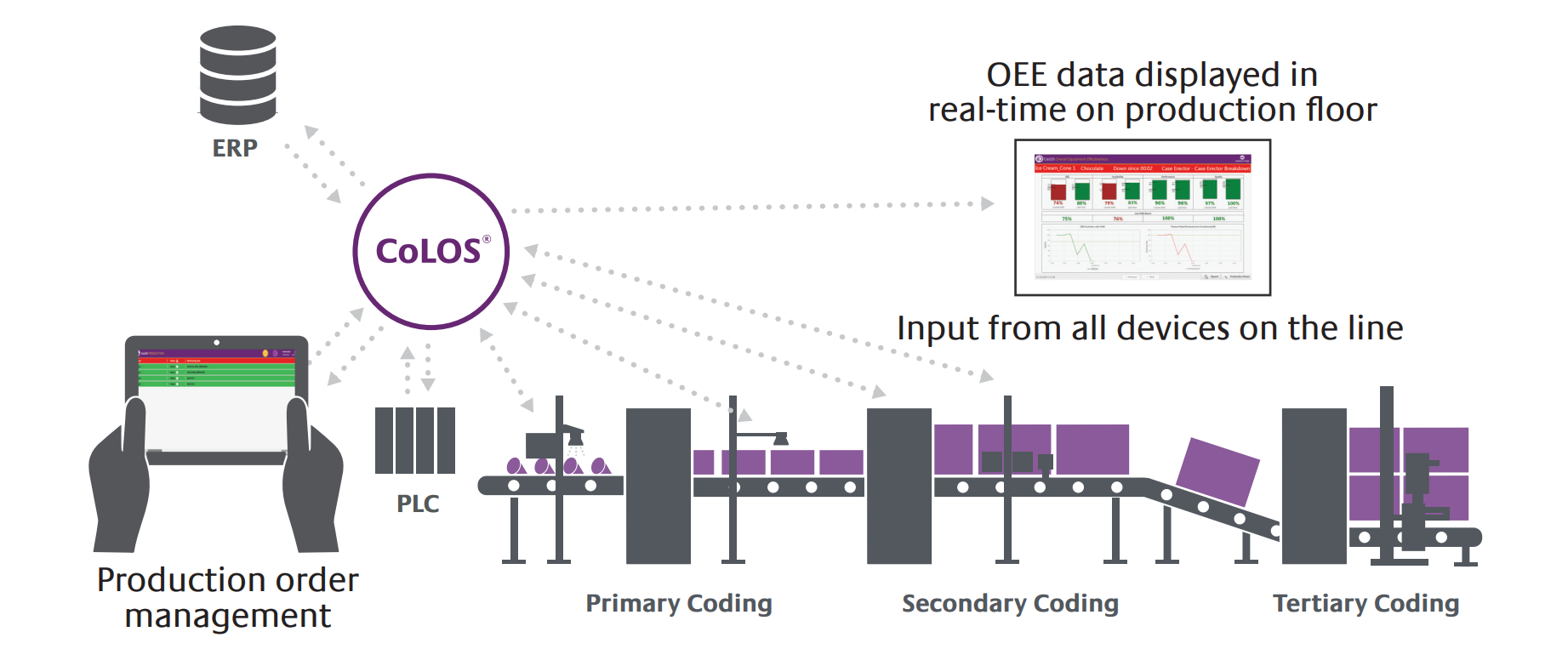

CoLOS® software was created to meet the need for comprehensive control, management and monitoring of industrial printing equipment on the production line – from printers, PLCs to inspection and machine vision systems.

- Hotline: 0965 800 166

1. General introduction to CoLOS software

In modern manufacturing and packaging environments, ensuring accuracy, speed and efficiency is vital. CoLOS® software was created to meet the need for comprehensive control, monitoring and management of industrial printing equipment on the production line – from printers, PLCs to inspection and machine vision systems.

With an intuitive interface, powerful connectivity, and real-time data analytics, CoLOS helps factories:

- Reduce printing errors

- Increase operating efficiency

- Optimize overall equipment effectiveness (OEE)

- Make strategic decisions based on real data

2. Outstanding features of CoLOS software

Manage the entire chain from a single point

CoLOS allows you to access and control all production orders, devices and print parameters from a single interface – saving time and reducing errors.

Automate the printer setup process

One-click to enter messages, set up print content, and sync with ERP systems. This eliminates manual errors and increases consistency between shifts.

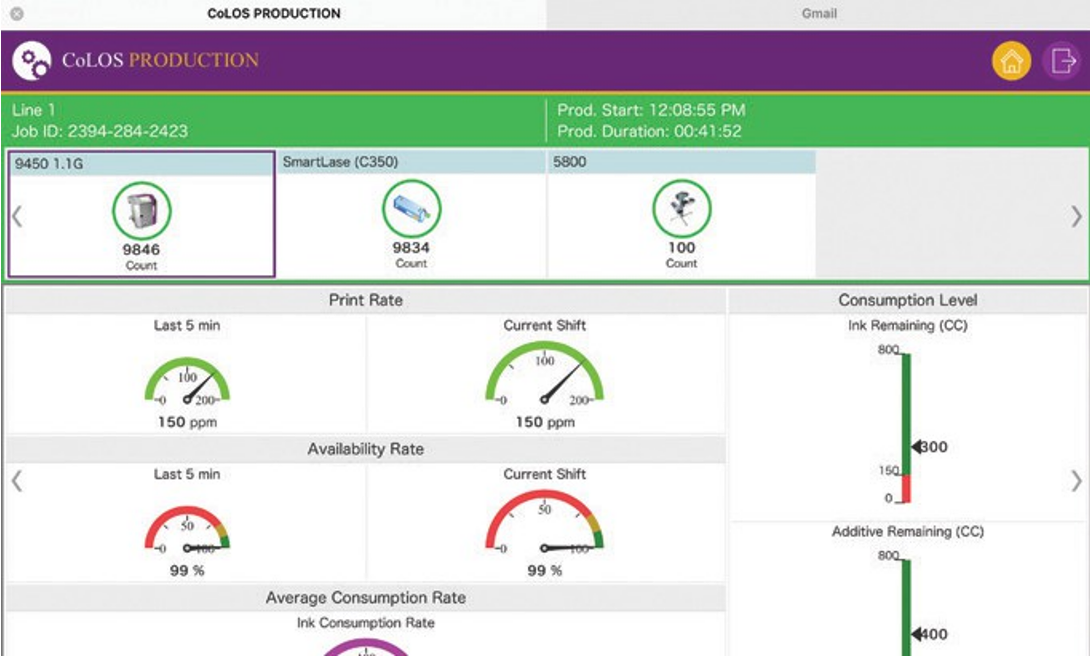

Monitor printer performance in real time

The software records and analyzes indicators such as:

- Print speed

- Uptime

- Ink consumption

- Print quality

- Error frequency and instantaneous warning

From there, the factory can proactively maintain, quickly handle errors and optimize the printing process.

OEE analysis and production line data

CoLOS provides a comprehensive view of device performance, helping you:

- Identify bottlenecks

- Optimize capacity

- Upgrade machines and processes based on real data

- Quality control and continuous efficiency improvement

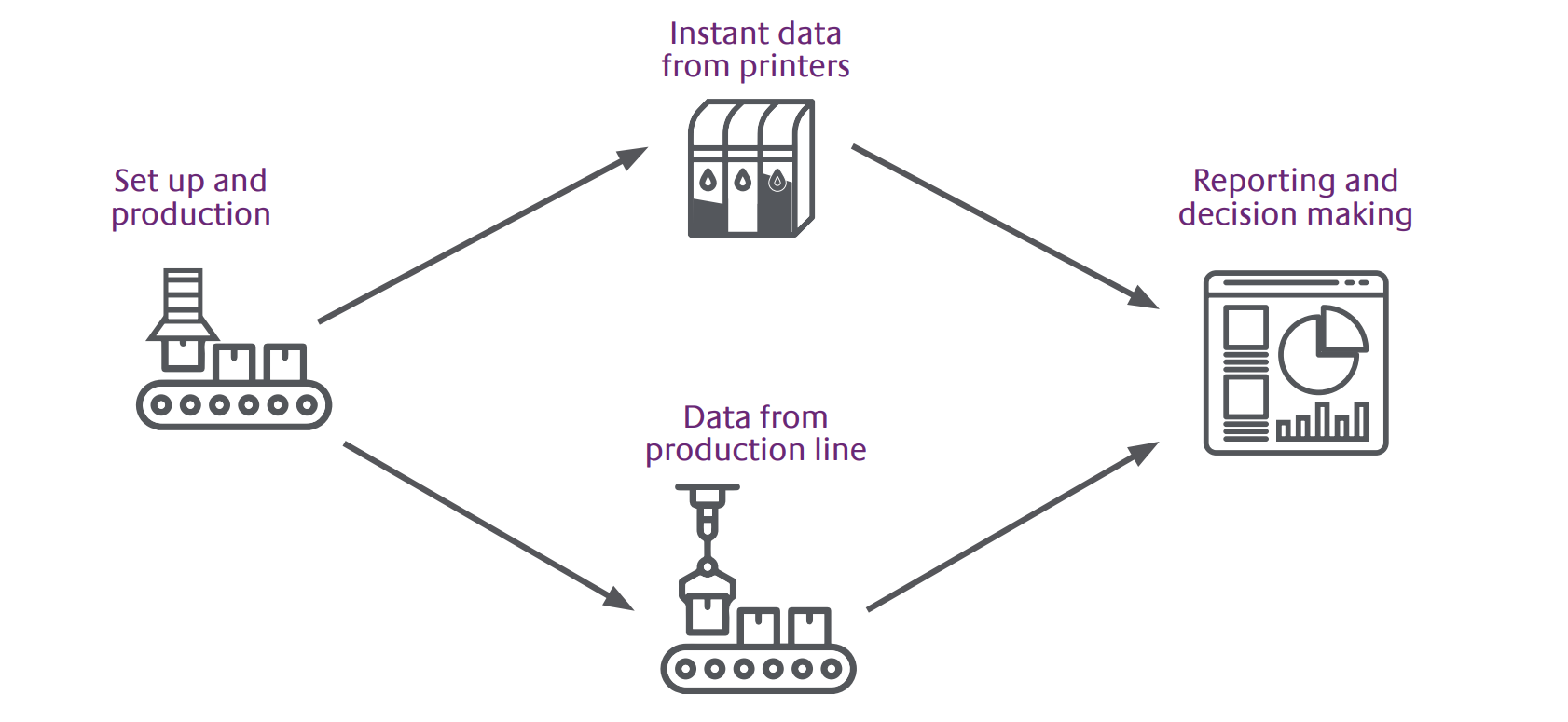

Detailed reporting, decision support

The software automatically generates various reports for analysis and comparison, including:

- Printer performance reports by shift, by device

- Error analysis, quality, printing speed

- Overall line OEE report

- Report on material usage (ink, labels, etc.)

3. Benefits of using CoLOS software

- Increase Productivity : Efficiently control printers and lines to improve output

- Reduce errors : Setup automation eliminates human error

- Cost Savings : Minimize downtime and material waste

- Continuous Improvement : Data analysis helps detect and improve weaknesses in the manufacturing process

- Optimize resources : Make the most of printers, equipment and manpower

4. Professional implementation and support services

We not only provide software, but also come with a complete service package to help you deploy effectively:

- Survey & consult solutions suitable for factory characteristics

- Turnkey Deployment : Includes software, hardware, system integration and training

- Fast and flexible technical support & maintenance

Learn more about CoLOS printer control and management software here:

5. Conclusion

CoLOS® printer control and management software is the ideal solution for manufacturing and packaging plants looking to optimize their printing lines, reduce errors and make decisions based on real-world data.

Don’t let small printing errors affect big efficiency – Let CoLOS accompany you on your journey to digitally transform your production line.

For advice on the appropriate CoLOS® software solution for your production line, please contact:

Hotline: 0965 800 166

Website: etekpackmachine.com

We are ready to accompany you on your journey to optimize production!