Automatic Ultrasonic Tube Filling and Sealing Machine

Adopt ultrasonic welding technology, no need for heating time, welding is more stable and neat, no deformation and low rejection rate less than 1%

- Productivity: 20-25 products/minute

- Tube diameter: 13-50mm

- Tube height: 70-250mm

- Hotline: 0965 800 166

In the era of increasing industrialization and automation, the need to improve productivity, reduce production costs and ensure product quality is becoming the top priority of many businesses. To meet these strict requirements, the HX-006 Automatic Tube Filling and Sealing Machine was born as a comprehensive, intelligent and effective solution for modern packaging lines.

1. Outstanding advantages of HX-006 filling machine

- Advanced ultrasonic welding technology

The outstanding difference of this product is the modern ultrasonic welding technology – allowing quick sealing, without the need for heating time like traditional methods. Thanks to that, the welding process becomes stable, highly aesthetic , avoiding deformation of the pipe edge. The rate of defective products is extremely low – less than 1% , helping businesses save on raw material costs and time.

- High productivity, optimal production efficiency

With the ability to fill and seal 20-25 products/minute , the HX-006 machine meets the production needs of medium and large scale.

- Various pipe sizes

The machine supports tube diameters from 13-50mm and tube heights from 70-250mm , suitable for many different types of products. From cream tubes, gels, ointments to packaged foods, users can flexibly change the mold to meet each individual product type.

2. Widely used in many fields

Automatic tube filling and sealing machine is not only limited to cosmetics industry but also widely applied in:

- Food and beverage industry : Packaging sauces, dips, nutritional gels, instant products.

- Pharmaceutical industry : Filling ointments, skin creams, antibacterial gels…

- Chemical and light industry : Packaging of glue, polishing cream, special chemicals.

- Machinery and hardware industry : Filling of lubricating grease in tubes.

3. Automatic operating process

The machine operates in a closed cycle with the following steps:

- Manually load tubes into the system.

- The cylinder positions and delivers liquid into the tube with high accuracy of ±1g.

- Sealed by ultrasonic technology , ensuring durability and aesthetics.

- Cut off the excess tube , then push the finished product out .

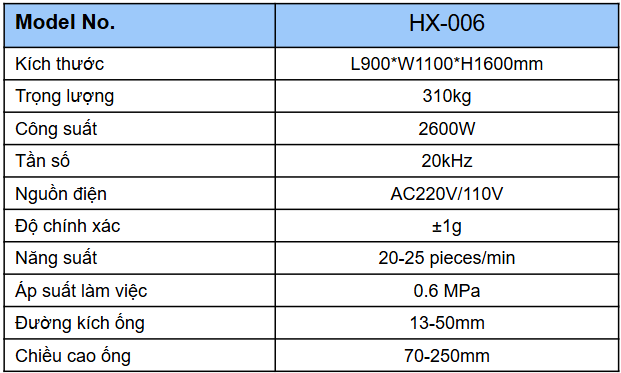

4. Detailed specifications

Below is detailed information about the product Automatic Tube Filling and Sealing Machine HX-006

5. Why should you invest in the HX-006 filling machine?

- Increase productivity , reduce labor costs.

- Ensure product quality and reduce defect rate.

- Optimize packaging process with intelligent automatic system.

- Modern design, compact , easy to install and maintain.

👉 Contact now for advice and quote

If your business is looking for a modern, efficient and economical packaging solution – the HX-006 Automatic Tube Filling and Sealing Machine is the perfect choice.

Please contact us for more detailed product advice, preferential quotes and lifetime technical support!