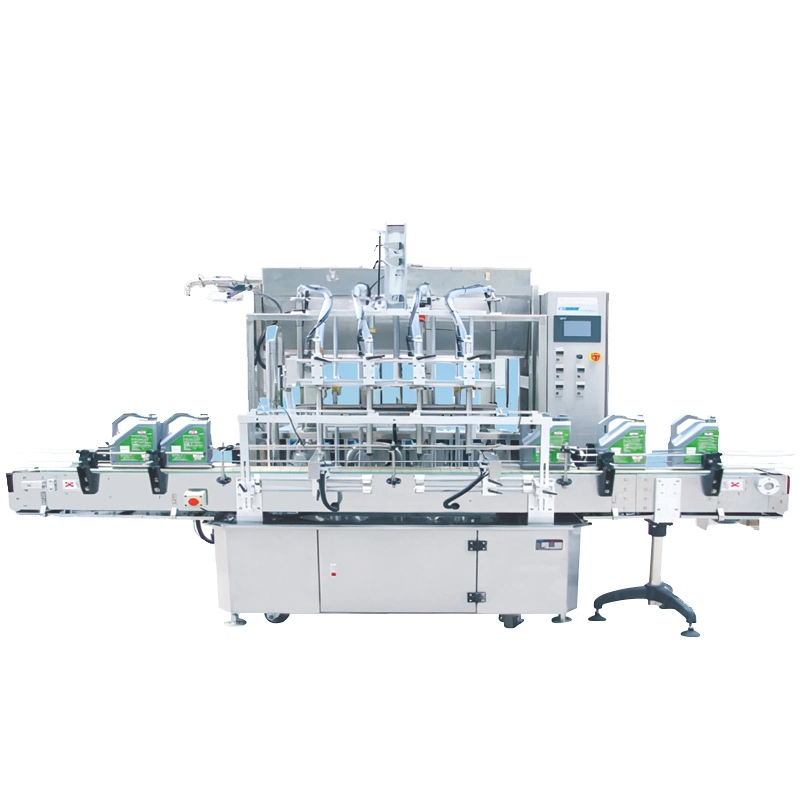

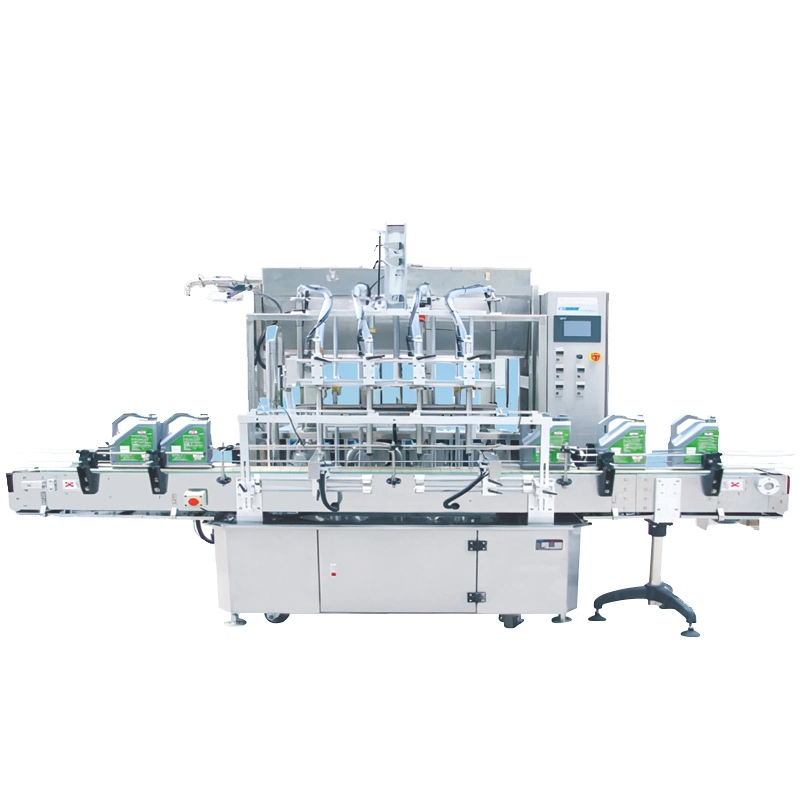

Automatic Servo Piston Filling Machine

The machine is suitable for filling low to high viscosity liquids. Widely used in the industries: chemicals, pharmaceuticals, pesticides, cosmetics, food and other fields.

Filling capacity: 100ml – 20 liters

Filling error: ± 0.5%

- Hotline: 0965 800 166

In the era of industry 4.0, automation plays a key role in optimizing production processes, improving productivity and reducing costs. For businesses operating in the field of liquid production, automatic filling machines are an indispensable investment. Among them, the Automatic Filling Machine with Vane Pump stands out as a superior solution, flexibly meeting all filling needs from small to large capacity, from low to high viscosity liquids.

1. General introduction of Automatic Filling Machine with Vane Pump

Automatic Vane Pump Filling Machine is designed to handle a wide range of liquids, from thin liquid products such as soft drinks, cleaning chemicals to highly viscous products such as lubricants, cosmetics, or pesticides.

This equipment is an ideal choice for large-scale production plants where high speed and reliability are required. The machine is made of high-quality, corrosion-resistant and easy-to-clean materials, ensuring food and pharmaceutical hygiene and safety standards.

2. Outstanding features of Automatic filling machine with vane pump

- Outstanding Flexibility: Filling capacity from 100ml to 20 liters, suitable for many types of packaging.

- High Accuracy: Error only ±0.5% , meeting strict requirements of pharmaceutical and chemical industries.

- Widely Used in Many Industries: Thanks to its versatility and accuracy, the Automatic Vane Pump Filling Machine is widely used in many fields, including:

- Food and beverage: Soft drinks, cooking oil, sauces, milk, syrups, etc.

- Consumer goods: Laundry detergent, fabric softener, dishwashing liquid, industrial detergents.

- Medical and pharmaceutical: Liquid medicine, antiseptic solution, medical chemicals.

- Chemicals: Solvents, industrial detergents, agricultural chemicals.

- Cosmetics: Shampoo, shower gel, lotion, perfume, etc.

- Machinery & Hardware: Oils, lubricants, other industrial chemicals.

3. Complete Automatic Filling Process

The machine is designed with a closed automatic filling process, optimizing performance and minimizing human intervention, including the following steps:

- Bottle level

- Split product lanes

- Lower the filling nozzle and fill the bottle.

- Anti-drip and spout lift mechanism

- Close the lid

- Move the product to another stage.

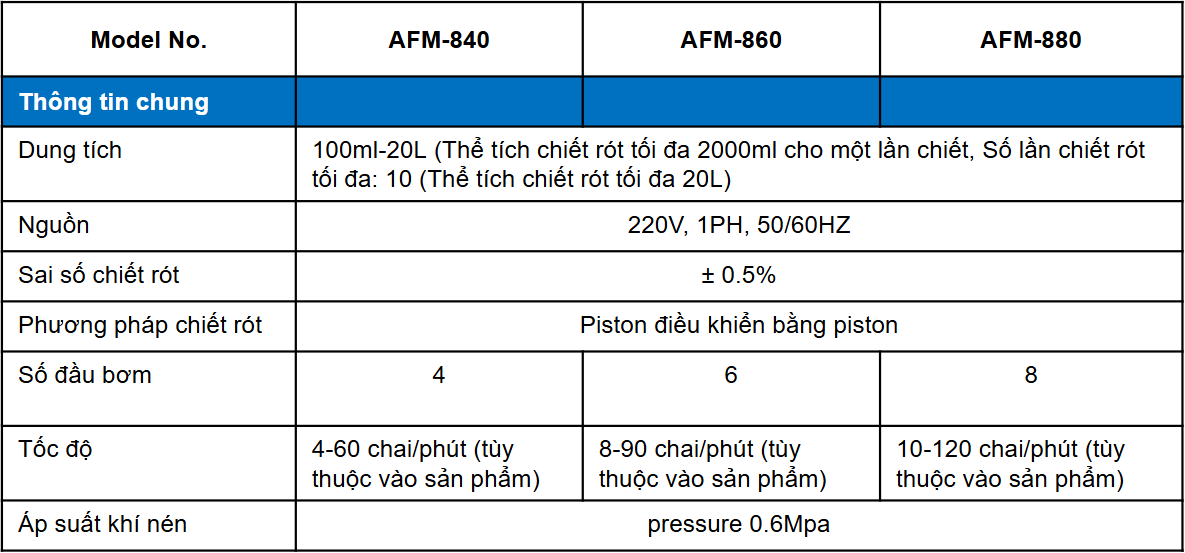

4. Detailed specifications

To meet different production requirements, the Automatic Vane Pump Filling Machine is offered in various models, providing flexibility in choice:

5. Benefits for businesses when investing in products

Investing in a Vane Pump Automatic Filling Machine brings many strategic benefits to businesses:

- Increase productivity : Speed up production to meet market demand.

- Improve quality : Ensure product consistency, increase reliability.

- Reduce labor costs : Limit manual labor, reduce errors.

- Optimize raw materials : Reduce waste, increase profits.

- Hygiene and safety guaranteed : Easy to clean, meets industry standards.

- Flexible production : Filling many types of capacity/liquid, easy to change products.

The Automatic Vane Pump Filling Machine is a comprehensive, advanced technological solution for all liquid manufacturing enterprises. With its smart design, high precision, flexibility and outstanding productivity, the machine not only helps optimize the production process but also contributes to improving product quality and enhancing competitiveness in the market.