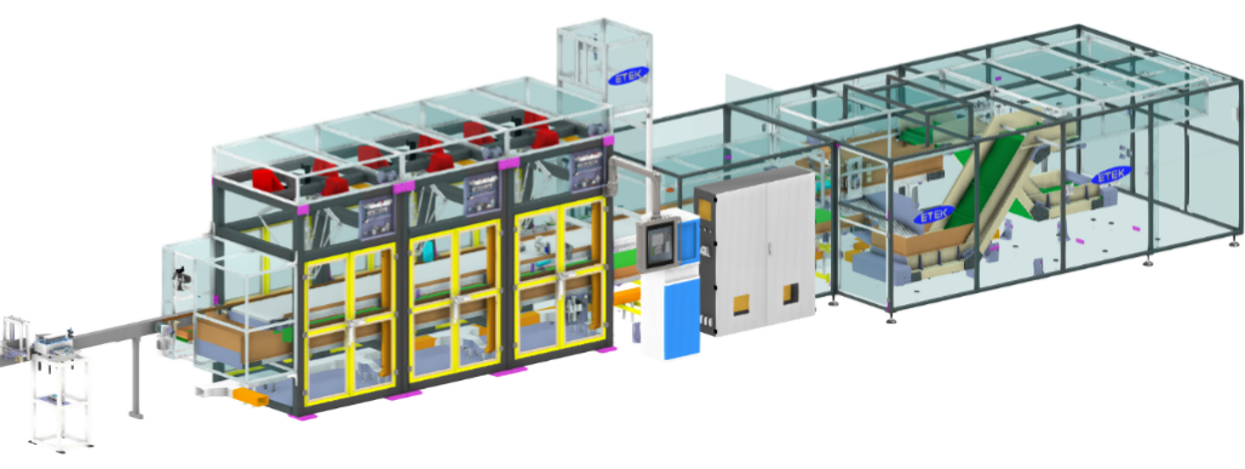

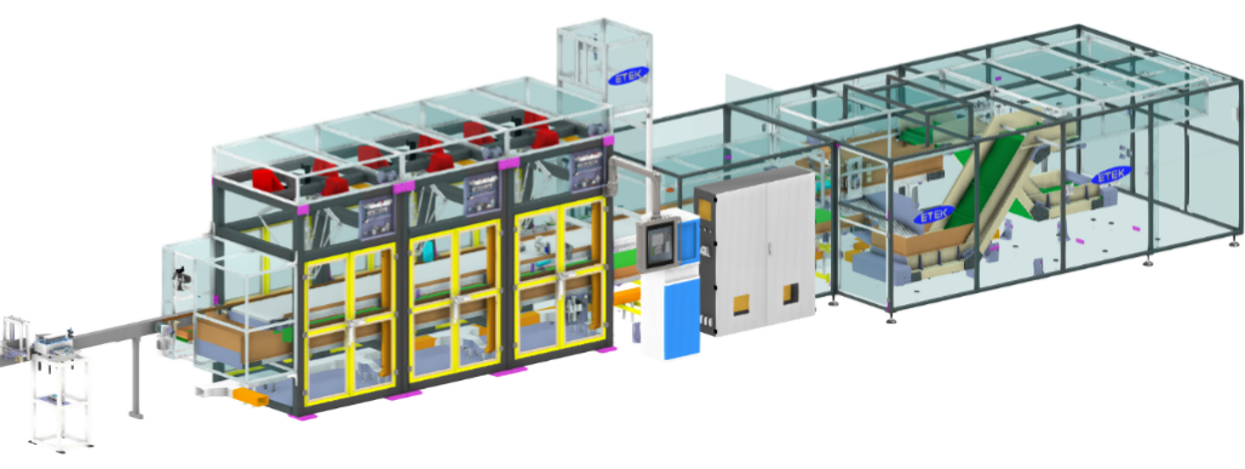

Automatic Cartoning System For Bottles

Highlights

Automatic cartoning system for bottles using high-speed Delta robot, precise picking – stacking – cartoning, speed 200 products/minute. Flexible change of size, stacking pattern. Integrated carton erecting/gluing machine, weight checking, barcode. Labor saving, easy to operate, ISO & food hygiene standard

Support Center (8:00 - 17:00)

- Hotline: 0965 800 166

1. Introduction to the bottle capping system

The automatic cartoning system for bottles is a modern technological solution, integrating Delta high-speed robots to automate the entire process of arranging, sorting and packing bottles accurately, quickly and synchronously. The product is especially suitable for businesses in the food, consumer and large-scale bottled goods manufacturing industries.

2. Featured Applications

- Food industry: milk, soft drinks, cooking oil, spices…

- Consumer goods industry: Cosmetics, hand sanitizer, detergent, conditioner, etc.

- Industrial module manufacturers have high demands on speed and accuracy in packaging.

3. Benefits of using the system

- Outstanding processing speed – up to 200 products/min , optimal flow rate.

- Save labor costs, minimize the risk of errors when performing manual operations.

- Space-optimized factory with compact, modern design.

- Perfectly synchronized with animal systems, labeling, quality control,…

4. Flexible features & easy expansion

- Support flexible model changes according to product needs and box types.

- Custom size products are easily customized without changing the entire system.

- Smart information integration with packing machines, construction machines, barcode and weight checking systems.

- Change the starter (tool) flexibly according to different bottle shapes.

5. Technical parameters of bottle packing machine

- Material: Powder coated steel, Stainless steel.

- Speed: about 200 sp/min.

- Robots: 3 Delta robots.

- Control: Custom PLC.

- Display: Customize the HMI screen.

6. Quality commitment from the manufacturer

- Optimal design – easy to operate and maintain

- Meet ISO standards, ensuring food hygiene and safety

- On-site warranty – fast technical support

- Optimize performance, save energy

7. Why choose Automatic Cartoning System For Bottles?

- Modern solutions, intelligent automation.

- Improve productivity – optimize costs.

- Easily integrate production line products.

- Increase accuracy, reduce product exit failures.