BEVERAGE CUP PACKAGING LINE WITH CAPACITY OF 48,000 PRODUCTS/HOUR

A beverage factory in Vietnam has decided to increase its production capacity by investing in an automatic packaging system with screw technology – the first to be deployed in the domestic market.

Background & Challenges

The client is one of the leading enterprises in the beverage industry, providing a wide range of products from soft drinks to healthy product lines. With a distribution network spanning 64 provinces and cities, the brand currently accounts for more than 35% of the market share. In the post-Covid-19 context, the fast-moving consumer goods industry has witnessed strong recovery and growth, leading to the need to expand production, improve quality and optimize costs.

Problems the factory is facing:

- Production pressure: Demand exceeds supply, forcing factories to increase production speed to avoid missing out on market opportunities.

- Requirements for appearance and packaging: Fierce competition from both imported and domestic products requires products to be upgraded in appearance, design and aesthetics.

- Strict quality control: A small mistake in packaging can greatly affect brand reputation.

- Digitalization process: As a pioneer in the industry, the factory aims for comprehensive digital transformation, starting with packaging automation.

Requirements

Fully automated packaging

Previously, 100% of the water cup packaging process was done manually. This caused the following situation:

- Overloaded workers cannot keep up with increased output.

- Errors are likely to occur during the sorting and packing process.

- Increased risk of food insecurity.

Application of modern technology

Requires integration of advanced technology, including:

- Synchronized link between devices in the chain.

- Intelligent control signal transmission.

- Monitor quality and production process in real time.

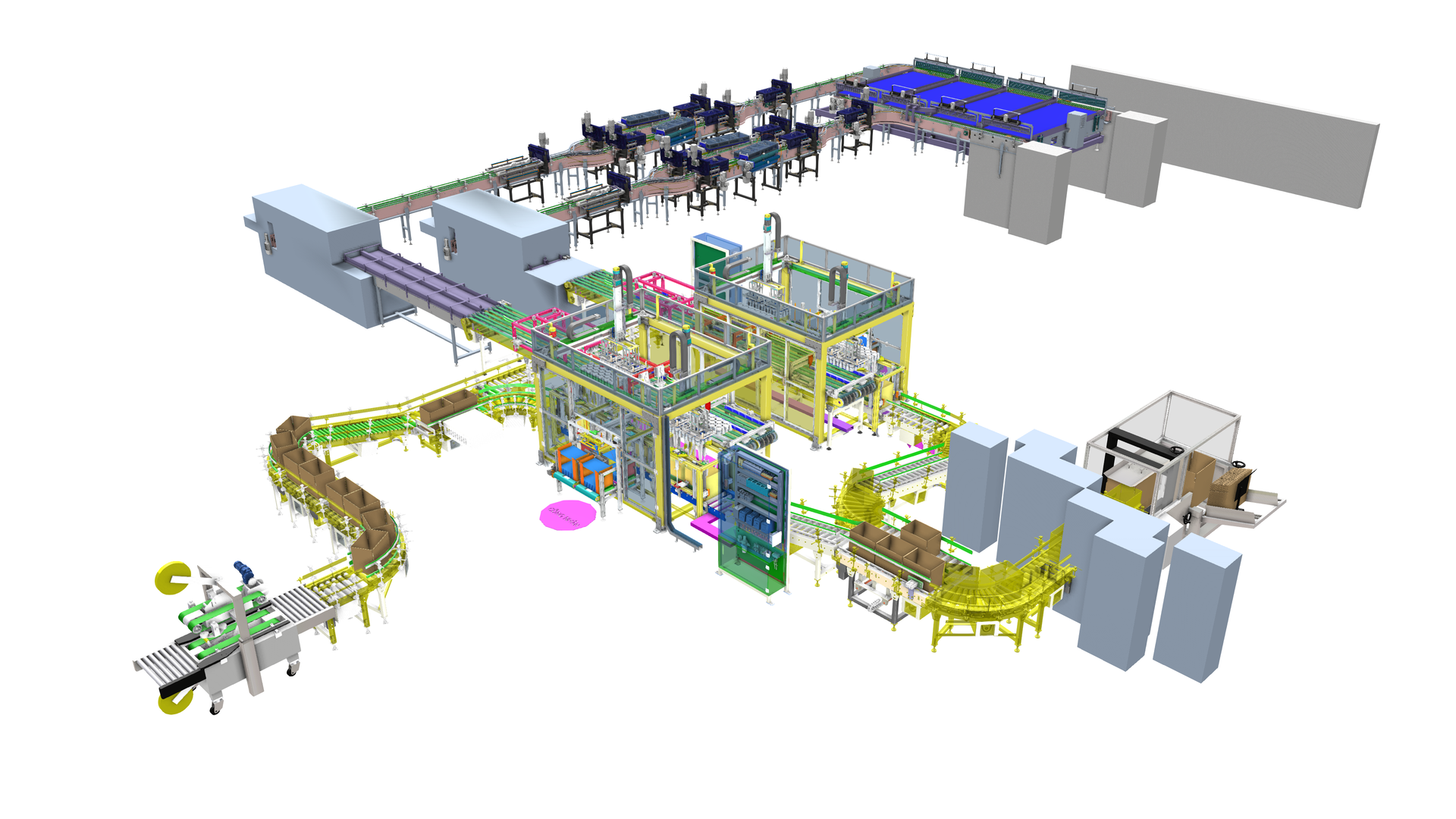

Total solution from ETEK

ETEK was selected as the general contractor to design and implement a complete automated packaging system, ensuring:

Increase capacity up to 48,000 products/hour .

Applying torsion shaft technology for the first time in Vietnam, including the following steps:

- Split lane

- Flip the glass

- Merge lanes

- Create block

Main components of the chain:

- Product feeding conveyor

- Split lane / flip cup / merge lane / block creation (custom design)

- Heat shrink machine

- Batching and cartoning machine

- Straw Dropper

- Carton Erection and Sealing Machine

Breakthrough Technology: Torsion Shaft

As the highlight of the line, the screw shaft system was researched and designed by ETEK specifically for cup-shaped packaging products. Although this technology has been available in some countries, this is the first time it has been developed and integrated in Vietnam.

Technical challenges:

- High conveyor speed causes displacement of liquid containers.

- Cup deformation leads to block creation error (eg: 4 cups become 5 cups).

- Phenomenon of cup spillage when pressed in the wrong position.

- Interference between conveyor belts is jammed due to speed mismatch.

ETEK engineers used 3D simulation software combined with real-world calculations to optimize the design. The learning, assembly, and calibration process was shortened in a short time thanks to close coordination between departments.

Lightning Fast Progress: 4 Weeks from Requirement to Solution

Within just 28 days , all stages from survey, design, simulation, equipment selection to overall solution proposal were completed by ETEK and handed over to the customer.

Benefits for customers

- Increase productivity by 125%

- Reduce production costs by 4–8%

- Packaging defect rate <3%

- Ensure food hygiene >99%

- Meet more than 60% of factory digitalization requirements

Why choose ETEK?

- Pioneer in designing and implementing automatic packaging lines in Vietnam.

- Has carried out many large projects for prestigious brands such as Unilever, VinFast, P&G…

- Highly experienced team of engineers, capable of deploying multiple complex systems simultaneously.

The application of ETEK ‘s screw technology and packaging automation solutions has helped customers not only increase production but also take a big step forward in the journey of comprehensive digital transformation. The project is not only a technological breakthrough but also a milestone in the industrialization of beverage production in Vietnam.