Vision Inspection Solution

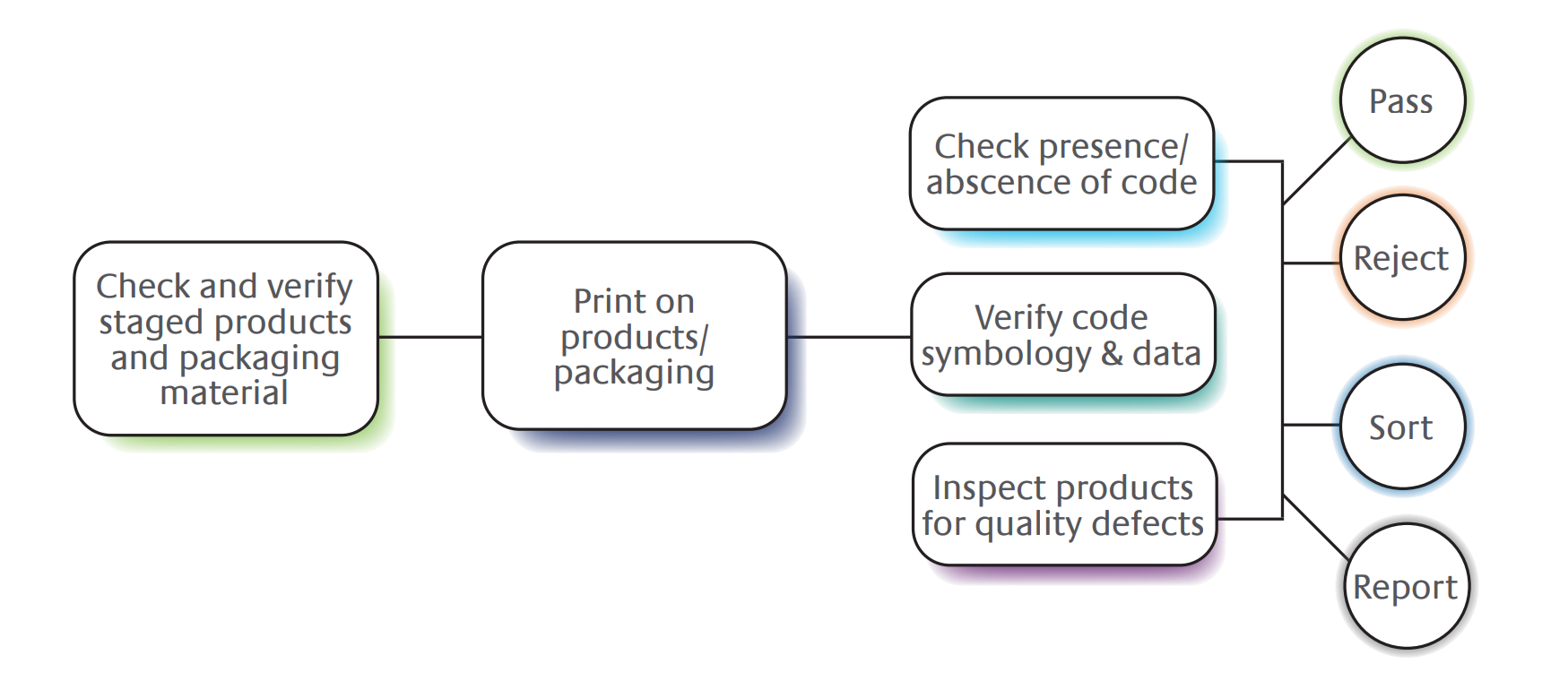

Vision Inspection Solution is a powerful solution that helps businesses automate inspection processes, detect errors in real time and optimize production efficiency . Designed specifically for packaging environments, this solution helps detect and resolve errors in codes, labels, packaging and products – even on curved, reflective, irregular or metallic surfaces.

- Hotline: 0965 800 166

1. GENERAL INFORMATION

In the modern manufacturing and packaging industry, ensuring the quality of labels, barcodes and packaging is a key factor in helping businesses maintain brand reputation , comply with legal regulations , and minimize the risk of product recalls . However, many businesses are still using manual inspection methods – which are time-consuming, prone to errors and affect production line efficiency.

Vision Inspection Solution is a powerful solution that helps businesses automate inspection processes, detect errors in real time and optimize production efficiency . Designed specifically for packaging environments, this solution helps detect and resolve errors in codes, labels, packaging and products – even on curved, reflective, irregular or metallic surfaces.

2. OUTSTANDING FEATURES

Barcode Check & Verification

- Check presence and accuracy of 1D/2D codes, QR codes, multi-line text

- Read codes on a variety of surfaces: curved, bright, reflective, irregular, dark or metallic

- Compare code with database or ERP to ensure correct information

Real-time error detection

- Identify printing errors such as blurred, misaligned, missing or incorrect codes

- Automatically remove defective products from the line

- Report incidents and generate instant alerts

Ensure packaging & product quality

- Check accuracy of packaging, labels, lids, seals, gaps, ingredient quantities

- Identify products by color, shape, weight, flavor…

- Detects misaligned, damaged or misplaced labels

Optimize operations & costs

- Increase line uptime, reduce manual intervention

- Reduced set-up and line changeover times

- Reduce data entry errors with touch panel and handheld scanner

- Centralize message design & management with CoLOS® software

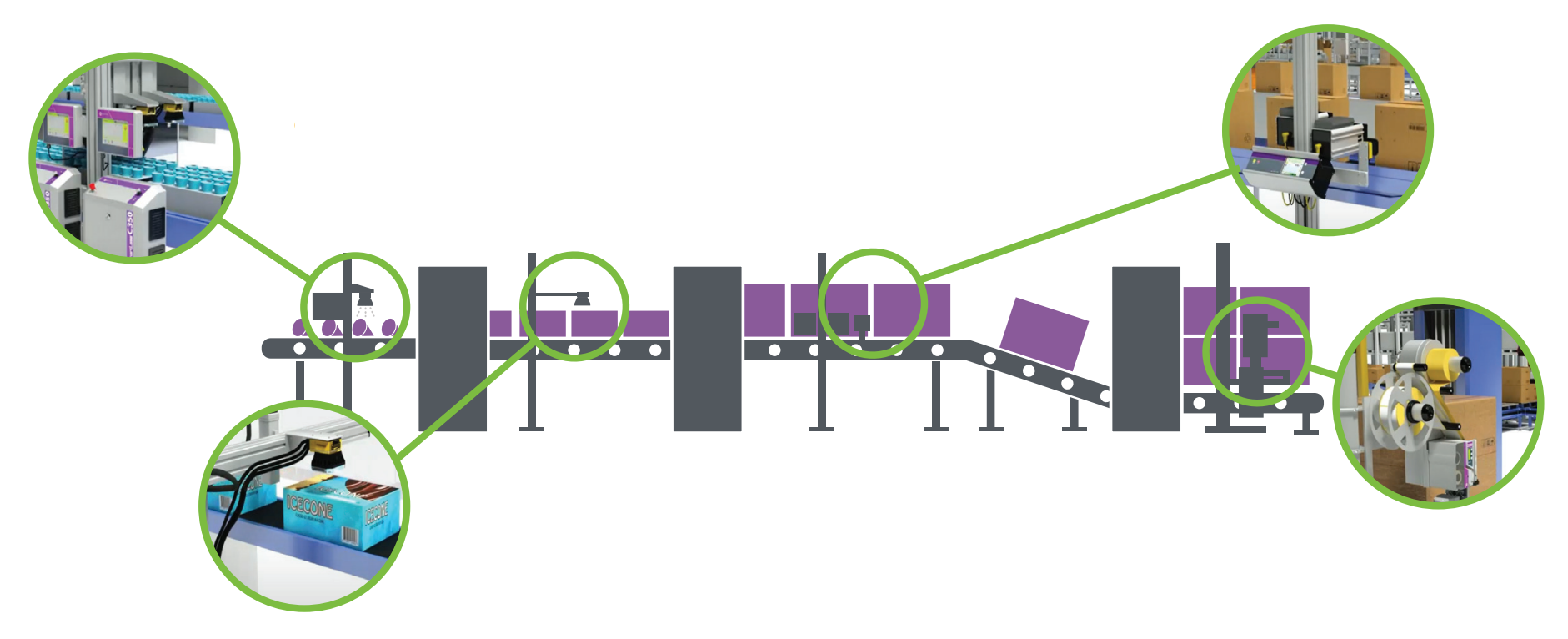

Standard testing and verification process:

3. TECHNICAL SPECIFICATIONS

| Category | Detail |

| Supported code types | 1D, 2D, QR code, multi-line text |

| Support surface | Flat, curved, reflective, metallic, dark/light background, uneven |

| Test speed | High, suitable for high speed lines |

| Special Features | Print error detection, code verification with ERP, defective product type, automatic reporting |

| System integration | Direct connection to databases, CoLOS® software, ERP, printing systems |

| Error classification | Blurry printed codes, incorrect data, defective packaging, missing components, incorrect or damaged labels |

4. CONCLUSION

Vision Inspection Solution is not only a tool to support product quality inspection but also an indispensable part of the enterprise’s automation and production capacity improvement strategy .

With instant error detection, ensuring code and label accuracy on all types of surfaces, Vision solutions deliver:

- Higher product quality

- Strict compliance with the law

- Optimize costs and resources

- Reduce risk and increase brand credibility

👉 Contact us now for advice and implementation of the Vision solution that best suits your production line!