Automatic Ultrasonic Tube Filling and Sealing Machine

HX-002 automatic tube filling and sealing machine adopts ultrasonic welding technology, no need for heating time, more stable and neat welding, no deformation and low rejection rate below 1%

- Productivity: 10-15 products/minute

- Pipe diameter: 13-50mm

- Tube height: 50-210mm

- Hotline: 0965 800 166

In the era of industry 4.0, the application of automation in the production and packaging process not only helps businesses save costs, but also optimizes production efficiency, improves product quality and ensures consistency. The HX-002 Automatic Tube Filling and Sealing Machine is a prominent device in the highly automated product line, suitable for many industries from food, cosmetics to chemicals and pharmaceuticals.

1. Ultrasonic welding technology in filling machine

Unlike traditional thermal welding methods, the HX-002 uses modern ultrasonic welding technology , which does not require a warm-up time. This not only saves energy, but also produces welds that:

- Neat and even

- No tube deformation

- High durability, airtight, chemical resistant

- Extremely low product defect rate – less than 1%

2. High productivity, cost savings, increased efficiency

The machine can process 10 – 15 products/minute , equivalent to 600 – 900 products per hour. With this speed, the device is suitable for both medium and large-sized businesses, helping to save labor and increase operating efficiency.

3. Flexible in design, compatible with many types of products

The HX-002 is compatible with a wide range of plastic pipes thanks to its adjustable capabilities:

- Pipe diameter: 13 – 50 mm

- Pipe height: 50 – 210 mm

- Product capacity: 6 – 500 ml

The machine can be widely applied to liquid, paste, gel or cream products with various volumes.

4. Smart operating process, optimal automation

The HX-002 machine performs a series of operations in automatic sequence, ensuring high efficiency and accuracy, the entire process is monitored via an intelligent electronic control panel with a modern touch screen:

- Tube loading : Manual, ensuring correct initial orientation

- Drop cylinder orientation down tube

- Filling : Cylinder dispenses exact desired volume

- Pull out the cylinder

- Ultrasonic sealing : Ensures tight and durable seal

- Trim excess pipe ends

- Push the finished product out

5. Multi-industry application, optimizing equipment investment

HX-002 tube filling & sealing machine is widely used in many fields:

- Food & Beverages: Ice cream, sauce, honey, butter, yogurt,…

- Cosmetics & consumer goods: Moisturizers, cleansers, shampoos, lipsticks, etc.

- Pharmaceuticals – Medical: Ointments, therapeutic gels, creams, etc.

- Chemicals – Engineering: Adhesives, detergents, paints, etc.

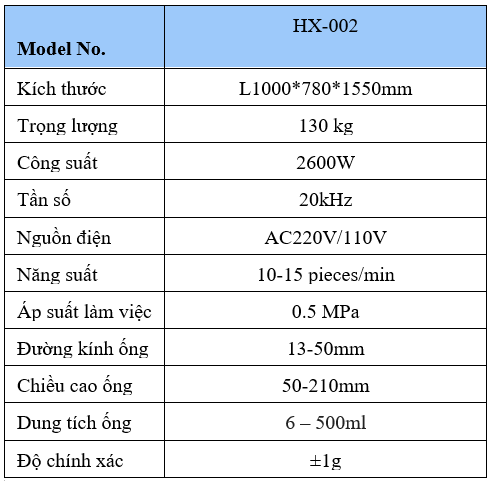

6. Detailed technical parameters of tube filling & sealing machine HX-002

7. Reasons why you should invest in the HX-002 filling machine right away

- Modern technology, no heating required

- Fast speed, increased productivity

- High accuracy, low error rate

- Flexible design, suitable for many industries

- Smart control system, easy to use

- Durable, easy to maintain, long term cost savings

The HX-002 automatic tube filling and sealing machine is a comprehensive solution for businesses that want to automate production processes, improve product quality and optimize costs. With modern technology, optimal design and high performance, this is definitely a worthy investment for any professional manufacturing plant.

📞 Contact us now for detailed advice and the best quote!

Nationwide delivery – Long-term warranty – Installation & operation support