Automatic Ultrasonic Tube Filling and Sealing Machine

Widely used in food, pharmaceutical, cosmetics, chemicals and other plastics, PE, aluminum multilayer tube.

- Safety protection: Equipped with safety device

- Stations: Ten stations (turntables)

- Anti-Drip: Fill Anti-Drip

- Tube type: Two-chamber tube

- Hotline: 0965 800 166

In the context of the increasingly developing industry and the demand for mass production with high precision, the automatic filling machine for two-compartment tubes has become the optimal choice for many businesses. Widely used in fields such as food, cosmetics, pharmaceuticals and chemicals, the HX-009S series is a comprehensive solution, helping to save time, increase productivity and ensure the quality of finished products.

1. Introduction to filling machine products

The two-compartment tube filling machine is a modern machine designed to fill products with two separate components into the same tube. Thanks to the pneumatic piston pump system and 10 flexible turntable stations, the machine can operate continuously at high speed and with extremely low filling error (±1%).

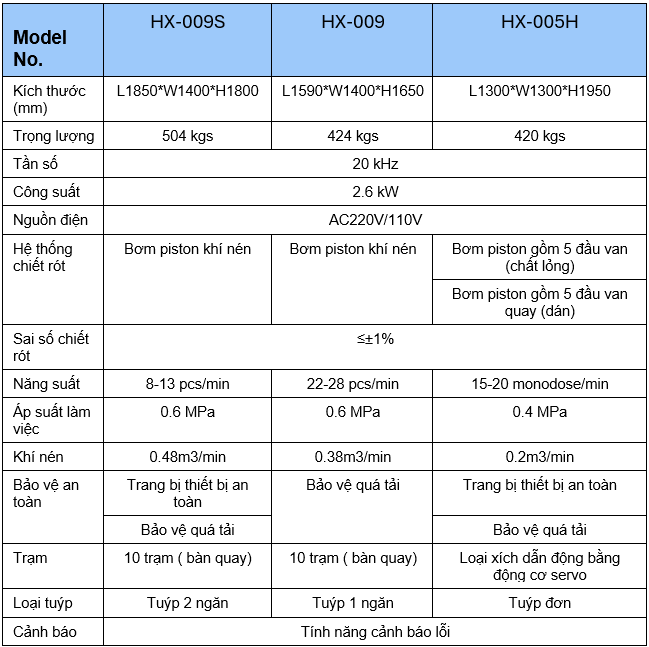

Main specifications:

2. Diverse applications in many industries

Thanks to its precise and flexible filling capabilities, the machine is widely used in the following industries:

- Food and beverage : Filling of two-component sauces, jams, creams.

- Pharmaceuticals : Filling of two-phase medicinal ointments and gels.

- Cosmetics : Moisturizer, sunscreen, beauty products with 2 separate compartments.

- Chemicals : Various types of glues, detergents, polishes with different ingredients.

- Plastic and packaging industry : Plastic tubes, aluminum tubes, multilayer tubes (PE, laminate…).

3. Optimized automation workflow

The machine operates fully automatically through 12 steps:

- Insert tube into auto feeder

- Automatically recognize and locate color markers

- Load the tube into the filling position

- Precisely adjust tube position according to color point

- Fixed tube orientation

- Feeding the material into the cylinder

- Accurately dispenses predetermined amounts

- Press the cylinder to seal

- Ultrasonic sealing

- Trim excess tube tip

- Push the finished product out

- Finishing tube slides down into the tray

4. Outstanding advantages of two-compartment tube filling machine

- Fully automated, reducing operating manpower, increasing work efficiency.

- Effective anti-drip ensures hygiene and saves materials.

- Low filling error (±1%), ensuring uniformity and professionalism.

- Safety protection system for users and machine operators.

- Sturdy design, easy to maintain , suitable for modern production lines.

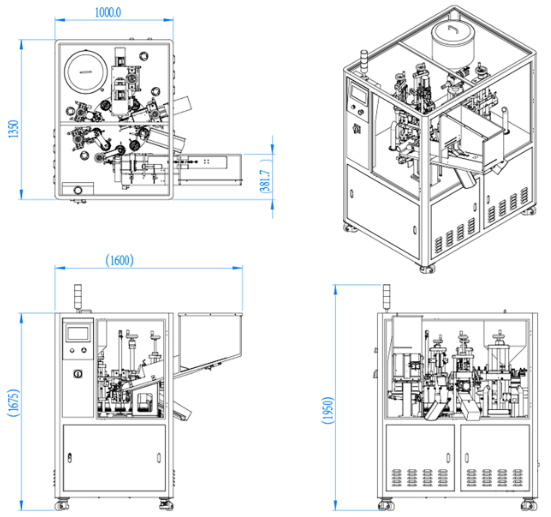

5. Product images – Clean and professional design

The machine has a modern appearance, sturdy stainless steel frame, easy-to-use touch screen control and wheels for flexible movement. The transparent design of the filling chamber allows easy monitoring of the operating process.

The automatic two-compartment tube filling machine is the perfect solution for businesses that want to improve production capacity, control quality and optimize costs. With precise filling ability, modern ultrasonic technology and safe design, the machine will be a great assistant in the food, pharmaceutical, cosmetic and many other fields.

📞 Contact us now for detailed advice and the best quote!

Nationwide delivery – Long-term warranty – Installation & operation support