Automatic Liquid Packaging Machine

Suitable for sauces, ketchup, egg whites, jams, mayonnaise, chili sauce, lotus seed paste, bean paste and other food fillings, as well as large-capacity beverages. The machine is also suitable for packaging non-food products such as oils, detergents, lubricants, industrial glues, etc. Especially suitable for liquid vacuum packaging applications.

- Speed: 5-20 bags/min

- Hotline: 0965 800 166

For liquid products, the need for an effective packaging solution that ensures quality and food safety is extremely urgent. To meet that need, the Liquid Vacuum Packaging Machine has emerged as a top choice, providing superior performance and maximum flexibility for a wide range of products.

1. General introduction to vacuum packaging machine

Liquid Vacuum Packaging Machine is a modern packaging solution, specially designed to process liquid and semi-liquid products efficiently, while optimizing air removal in the packaging.

Versatile product, suitable for both food and non-food applications:

- Food & Beverage: Sauces, jams, mayonnaise, food fillings, egg whites, bulk beverages.

- Non-food: Cooking oil, detergents, lubricants, industrial glues, liquid chemicals.

In particular, the machine is ideal for liquid vacuum packaging applications where air removal is vital to maintaining product quality and extending shelf life.

2. Widely used in many industries

The machine is widely used due to its flexibility and efficiency:

- Food & Beverage: Large scale packaging of agricultural products, processed foods, beverages.

- Consumer goods: Suitable for shampoo, shower gel, laundry detergent, cleaning agents…

- Medical & Chemical: Packaging of medical solutions and liquid chemicals with high precision and hygiene.

– With the ability to reach 5-20 bags/minute (bags/min) , the machine can meet a variety of production needs, from small to large scale. This speed helps optimize productivity, minimize waiting time and improve the overall efficiency of the production line.

3. Automatic packaging process

The packaging machine operates in a highly automated process, ensuring precision and hygiene in every step:

- Operator on HMI screen: enter product weight, packaging bag length

- Funnel to bring product down the pipe

- The packaging bag rolls feed the bags down the pipe.

- Product flows into bag

- Heat sealing system for bag sealing

- Finished products are shipped out.

4. Detailed specifications

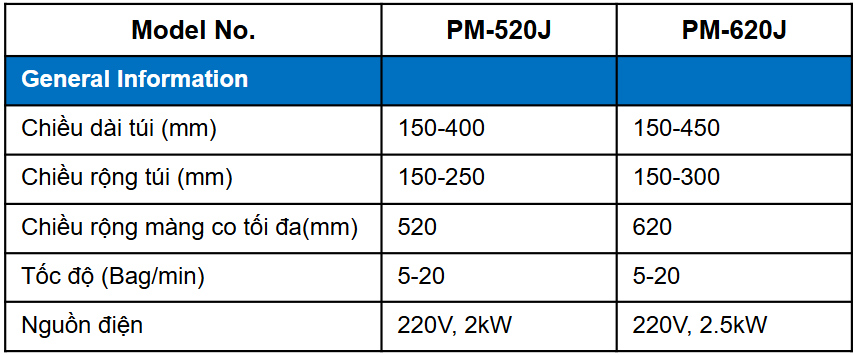

The Liquid Vacuum Packaging Machine comes in two main versions, PM-520J and PM-620J , offering flexibility of choice depending on specific production needs:

See more product videos here: Automatic Liquid Packaging Machine

5. Outstanding benefits when using liquid packaging machines

Benefits of investing in Liquid Vacuum Packaging Machine:

- Increase product quality: Long-term preservation, keeping flavor and nutrition.

- Improve productivity: Automation, fast packaging, meet high demand.

- Cost savings: Reduce labor, errors and waste.

- Hygiene: Closed design, stainless steel material, meets safety standards.

- Flexible: Pack a variety of products, easy to adjust bag size.

- Easy to operate and maintain: Friendly HMI interface, optimal structure.

Liquid Vacuum Packaging Machine is a strategic investment for any business looking for an efficient, reliable and cost-effective liquid packaging solution. With the ability to meet a wide range of production needs, from food to non-food, along with highly automated processes and outstanding performance, it not only improves product quality but also contributes to optimizing the entire supply chain, bringing sustainable competitive advantages in the market.