Automatic Box Erection Machine

The machine automatically sucks the carton and automatically forms the bottom seal. Time-saving and efficient, standardized production, labor-saving and economical. This carton erecting machine has been widely used in food, medicine, beverage, tobacco, daily chemicals, electronics.

Speed : 8-10 carton/min

- Hotline: 0965 800 166

In the context of modern industrialization, efficiency and automation are the keys to improving competitiveness for every business. Especially in the packaging industry, where speed and accuracy largely determine production efficiency, the Automatic Carton Erector emerges as a breakthrough solution, bringing superior optimization. This article will delve into the advantages, features and applications of this advanced machine line, helping your business save costs, increase productivity and standardize the packaging process.

1. General introduction of the product

The Automatic Carton Erecting Machine is an industrial equipment designed to fully automate the carton erecting and bottom sealing process. Instead of manual processes that are time-consuming and labor-intensive, the machine will automatically suck cartons from the warehouse, erect them, fold the bottoms and seal them quickly and accurately.

With the ability to operate continuously and stably, the Automatic Carton Erector is an ideal choice for large-scale factories and workshops that require high output and fast packaging speed.

2. Outstanding features and advantages

The Automatic Case Erector has many features and advantages that make it a worthy investment for any business:

- Fully automated: Vacuuming – erecting – folding – gluing boxes without manual intervention.

- Save time & labor: Build 8–10 crates/minute , reduce downtime.

- Economic efficiency: Reduce labor costs, reduce errors, save materials.

- Standardized quality: Firm, uniform packaging, good product protection.

- Durable, easy to operate: Industrial design, user-friendly control panel.

- Flexible size: Supports a variety of box sizes.

- Supports a variety of tapes: Choose the width to suit your needs.

- Energy saving: Stable operation with low power consumption.

3. Widely used in many industries

The versatility and efficiency of the Automatic Case Erector allows it to be widely applied in many different industrial fields, including:

- Food & Beverage: Confectionery, dairy, beverages, processed foods.

- Consumer goods: Household appliances, cosmetics, personal items.

- Medical & Chemical: Safe, sealed packaging protects products from external agents.

- Machinery & Hardware: Components, spare parts, tools.

- Cigarettes: Fast, uniform packaging.

- Electronic equipment: Precise packaging, anti-damage.

4. Operating Process of Automatic Crate Erection Machine

Despite being a high-tech device, the Automatic Crate Erector ‘s operating process is quite simple and seamless, ensuring optimal performance:

- Carton loading

- Carton installation

- Fold bottom & seal

- Carton loading

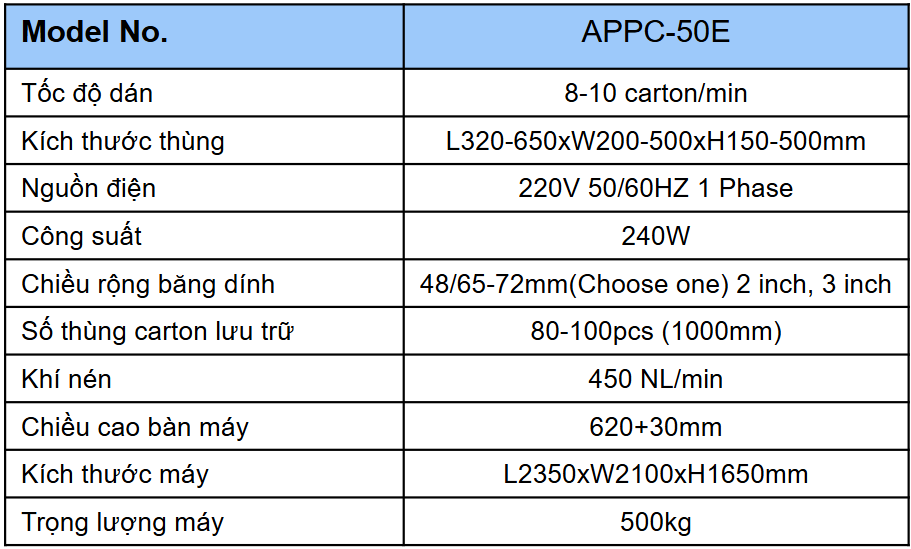

5. Detailed specifications

Below is a detailed specification table to help you better understand the performance of the Automatic Box Erector:

6. Choosing a Box Erector – A Smart Decision for the Future

Benefits of investing in Automatic Box Erection Machine:

- Increased productivity: Fast packaging, meeting large demand.

- Cost savings: Reduce labor, waste, optimize resources.

- Improve quality: Packaging is sturdy, uniform, enhancing brand image.

- Improve competitiveness: Handle large orders, shorten delivery time.

With outstanding advantages and diverse application capabilities, the Automatic Box Erection Machine is an indispensable tool for businesses that want to optimize packaging processes, improve performance and achieve sustainable development in today’s challenging business environment.