Automatic Servo Piston Filling Machine

This machine is designed to handle products ranging from watery to medium viscosity. This product can be widely used in the industries of: chemicals, pharmaceuticals, pesticides, cosmetics and food.

Filling capacity: 50ml – 5 liters

Air pressure: 0.6 Mpa

Capacity: 30 – 60 bottles/minute

- Hotline: 0965 800 166

Servo-controlled piston dosing filling machines have become the top choice of businesses, thanks to their superior accuracy, flexibility and high economic efficiency. This article will delve into the outstanding features, diverse applications and benefits that this machine line brings, helping businesses make the right investment decisions.

1. Overview of servo-controlled piston quantitative filling machine

Servo controlled piston metering filling machine is an advanced industrial equipment, specially designed to handle a wide range of products, from highly dilute solutions such as drinking water, soft drinks, to medium viscosity liquids such as shampoo, shower gel, agricultural chemicals or viscous foods.

With an operating mechanism based on a piston system controlled by a servo motor, the machine ensures extremely high accuracy in each filling. This not only helps save raw materials but also ensures volume uniformity for each product, an important factor in maintaining quality and brand reputation.

2. Outstanding technical specifications

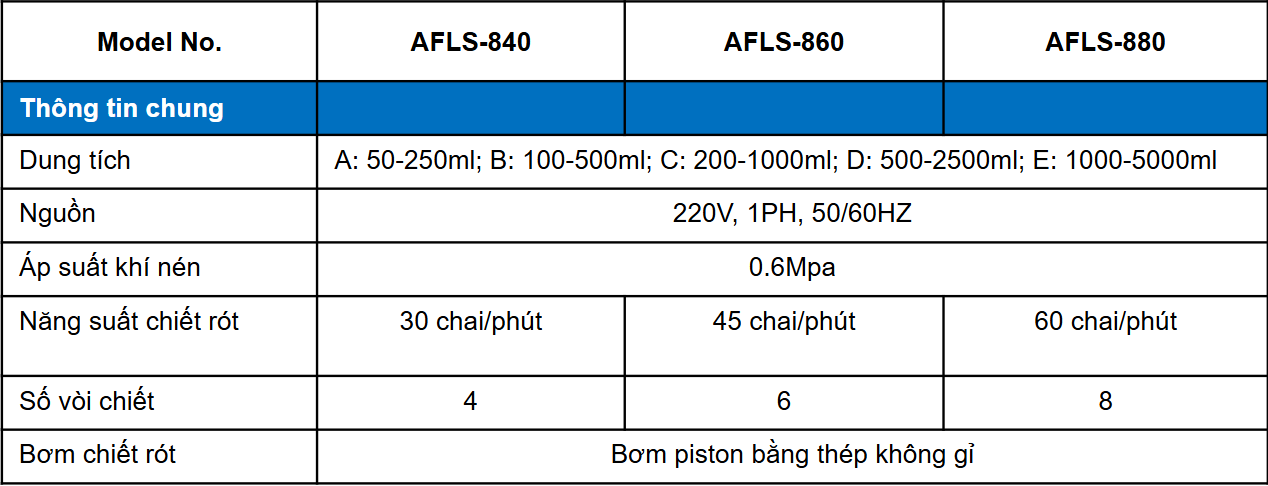

To better understand the machine’s capabilities, let’s take a look at the detailed specifications, clearly illustrated in the following table:

3. Outstanding advantages of quantitative filling machine

- High precision : Servo control piston, standard quantification, reduce error and waste.

- Product flexibility : Handles thin to medium liquids, capacity 50ml–5L.

- Increased productivity : Up to 60 bottles/minute, reducing dependence on manual labor.

- Hygienic & durable design : Stainless steel, easy to clean, HACCP/GMP certified.

- Stable & safe operation : Anti-drip, automatic nozzle lift, keep the area clean.

4. Widely used in industries

Servo controlled piston dosing filling machine is an ideal solution for many different industries:

- Food & Beverages : Water, milk, cooking oil, liquid spices, honey…

- Consumer goods : Shampoo, shower gel, laundry detergent, cleaning products…

- Medical & pharmaceutical : Syrup, liquid medicine, antiseptic solution…

- Chemicals & agricultural chemicals : Pesticides, solvents, liquid fertilizers…

- Cosmetics : Cream, lotion, serum, toner…

- Machinery & industry : Lubricants, coolants, maintenance chemicals.

5. Complete automatic operation process

One of the strengths of the servo-controlled piston dosing filling machine is its automatic and continuous operation, which optimizes the production flow:

- Bottle level

- Lower the filling nozzle and fill the bottle.

- Anti-drip and spout lift mechanism

- Close the lid

- Move the product to another stage.

6. Smart investment for business

Investing in a servo-controlled piston dosing filling machine is not just buying a piece of equipment, but investing in the sustainable development of your business. With its precise operation, high productivity, flexibility and outstanding durability, the machine helps businesses:

- Improve quality : Ensure volume consistency, increase brand reputation.

- Cost savings : Reduce material waste, optimize labor.

- Increase competitiveness : Increase output, quickly respond to market demand.

- Ensure hygiene and safety : Comply with strict hygiene standards.

- Sustainable investment : Precise operation, high productivity, flexibility and durability.

If your business is looking for an efficient, accurate and reliable filling solution, the servo-controlled piston filling machine is the choice not to be missed. Contact us today for detailed advice and to find the best solution for your production needs.