Automatic Filling and Capping Machine

The filling and capping machine is specially designed for small volume filling applications and fixed size bottles/jars. The machine integrates filling and capping functions in the same body, ensuring compact structure and high practicality.

- Speed: 0-20 m/min

- Hotline: 0965 800 166

In the context of modern industrialization, optimizing the production process is the key to increasing productivity and minimizing costs. For manufacturing industries that need to fill and cap liquids or semi-liquids into bottles and jars, the advent of the Fully Automatic Filling and Capping Machine has marked a breakthrough. This is not just a machine, but a comprehensive solution, bringing outstanding efficiency to all business sizes.

1. General introduction of fully automatic filling and capping machine

The fully automatic filling and capping machine is a specialized equipment designed to meet the needs of small-capacity filling and capping for fixed-size bottles/jars. The highlight of this product is the intelligent integration of two functions of filling and capping in the same machine body. This combination not only helps save production space but also optimizes the operating process, minimizes errors and increases speed.

With its compact structure and high practicality, the automatic filling and capping machine is suitable for a variety of production environments, from large-scale factories to small and medium-sized production facilities. The ability to fully automate helps businesses free up labor, focus on other stages in the supply chain, thereby enhancing competitive advantages in the market.

2. Outstanding advantages of the machine

- Process optimization : Automatic filling and capping, reducing downtime, increasing continuity.

- High precision : Standard filling, tight capping, minimizing loss and leakage.

- Cost savings : Reduce labor, cut operating costs.

- Easy to operate & maintain : Friendly interface, easy to clean and replace components.

- Durable design : Sturdy frame, anti-corrosion, long-term stable operation.

3. Diverse product applications

The machine’s versatility and efficiency make it an indispensable piece of equipment in many different industries:

- Food & Beverage : Filling milk, soft drinks, cooking oil, sauces, syrups…

- Consumer goods : Packaging shampoo, shower gel, detergent, liquid cosmetics…

- Medical & chemical : Filling liquid medicine, antiseptic, industrial solvent…

- Industry & Machinery : Applications for lubricants, greases, specialty chemicals.

4. Operating process of fully automatic filling and capping machine

The machine’s operating process is designed to be seamless and highly automated, including the following basic steps:

- Bottle level

- Pouring

- Level and set the lid

- Screw cap

- Get the product out

The entire process takes place automatically and continuously, at speeds of up to 0-20 meters/minute (equivalent to 15-20 bottles/minute depending on capacity and machine configuration), providing outstanding performance.

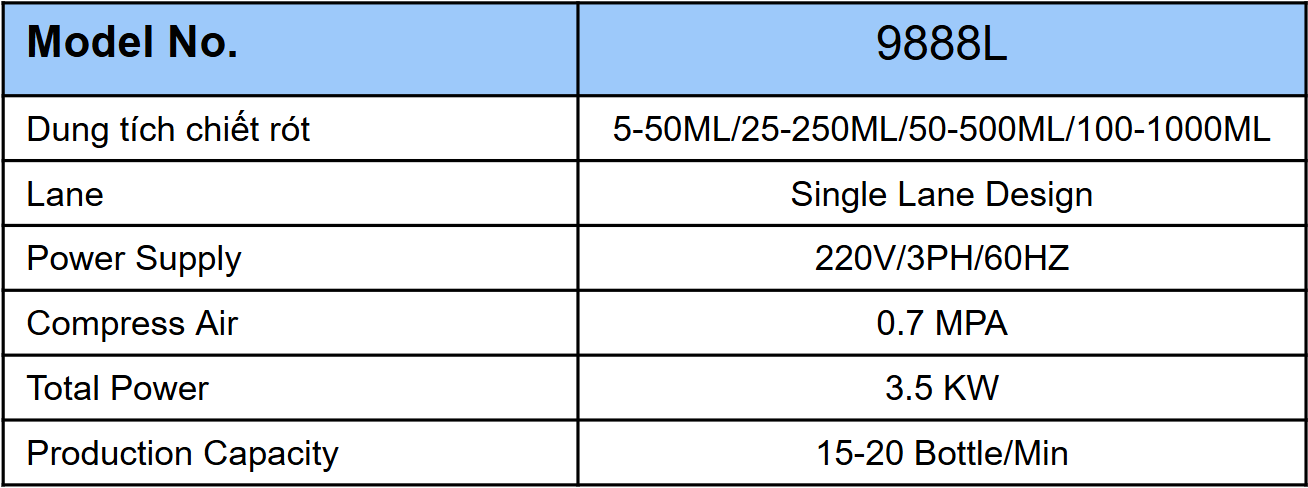

5. Specifications

To help customers better understand the machine’s capabilities, below is a detailed specification table of Model 9888L, one of the typical models of this machine line:

The Fully Automatic Filling and Capping Machine is a strategic investment for any business looking to optimize its packaging process. With its integrated filling and capping capabilities, high precision, superior productivity and wide range of applications, this equipment not only saves costs but also improves product quality and affirms the business’s position in the market.