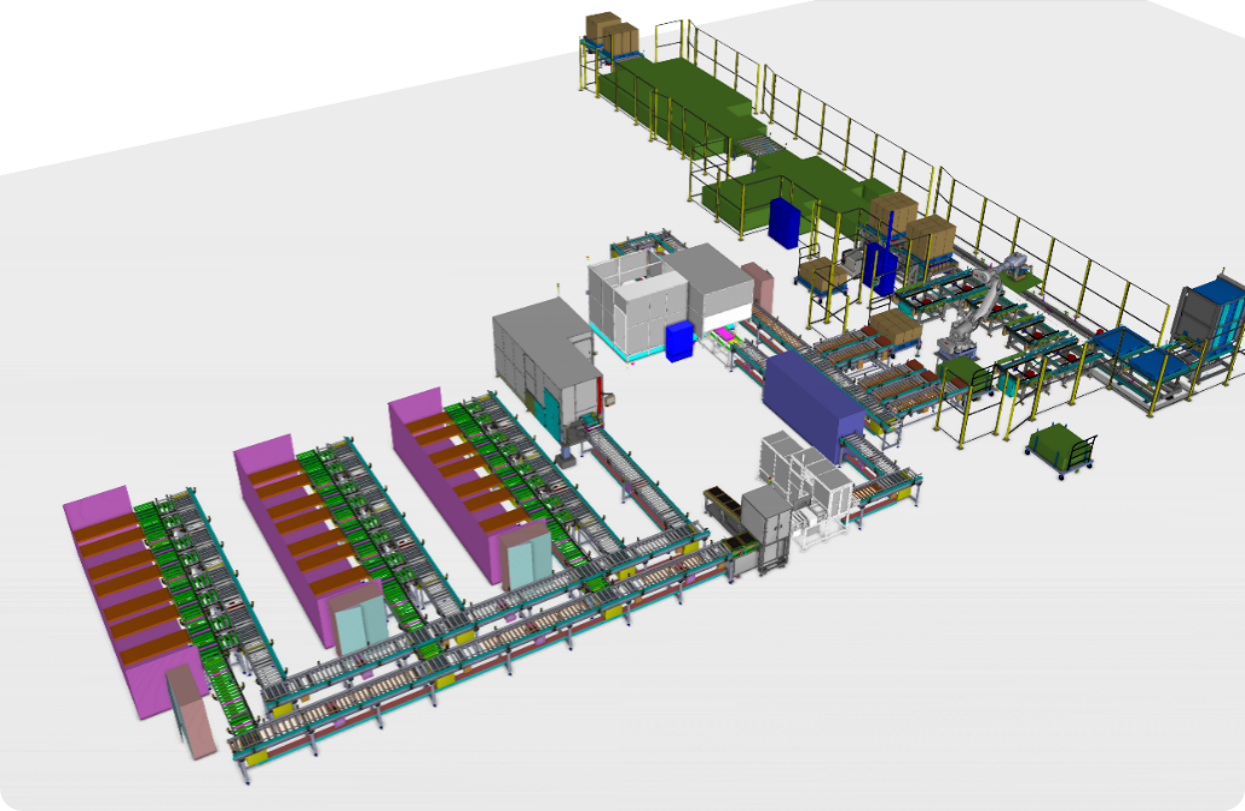

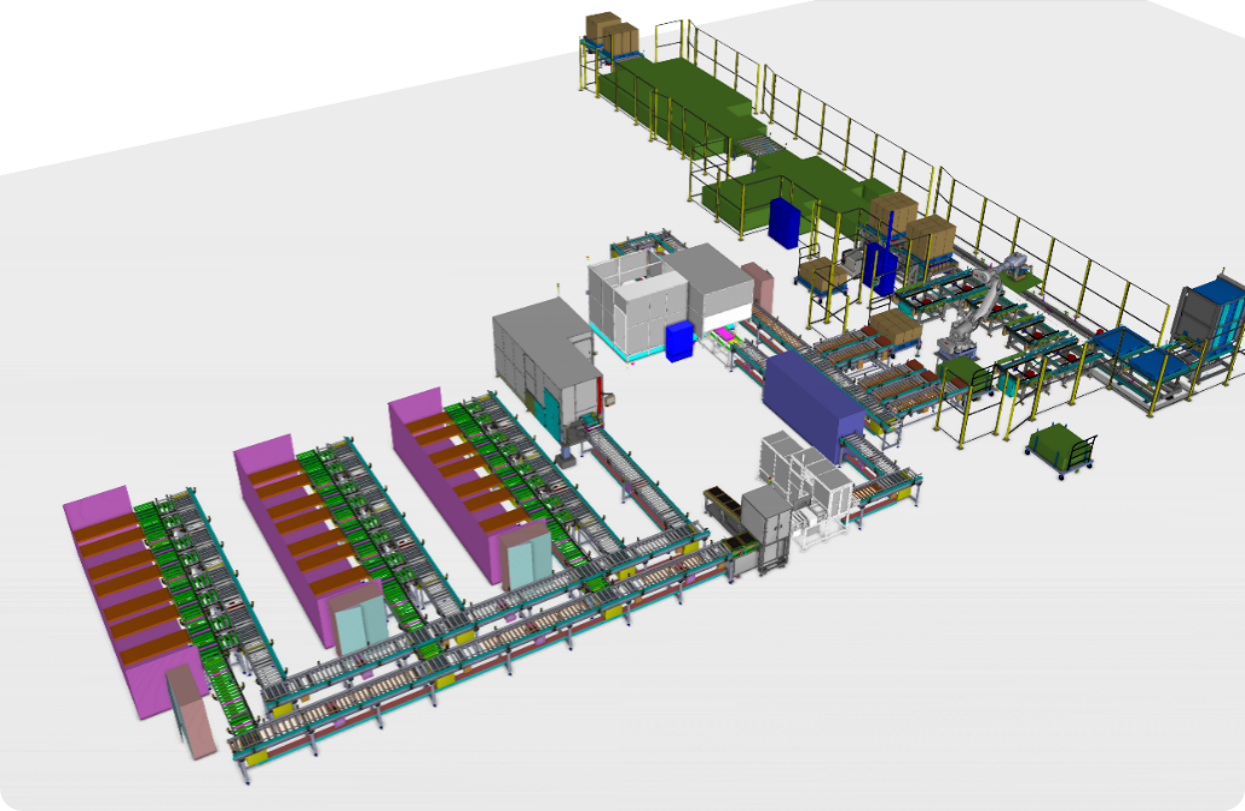

Automatic Battery Cell Packaging Line

Automatic Battery Cell Packing Line integrates the whole process: battery feeding, testing, bundling, packaging, labeling and QR printing.

High speed (40 cartons/minute), safe, flexible with smart monitoring software E-Factory. Suitable for car batteries, motorbikes, etc. Solution to optimize production, reduce labor, increase efficiency.

- Hotline: 0965 800 166

In the era of industry 4.0, automation is the key to improving efficiency and minimizing errors in production. The Automatic Battery Cell Packaging Line is an advanced solution that helps battery manufacturers optimize the packaging process, ensuring absolute quality, accuracy and safety.

1. Overview of Battery Cell Packaging System

The automatic battery cell packaging line is an integrated system of the following stages:

- Automatic battery level

- External quality inspection

- Arrange batteries in clusters

- Packed in carton

- Label and print QR code

The system operates fully automatically, minimizing manual intervention, improving consistency in each output product.

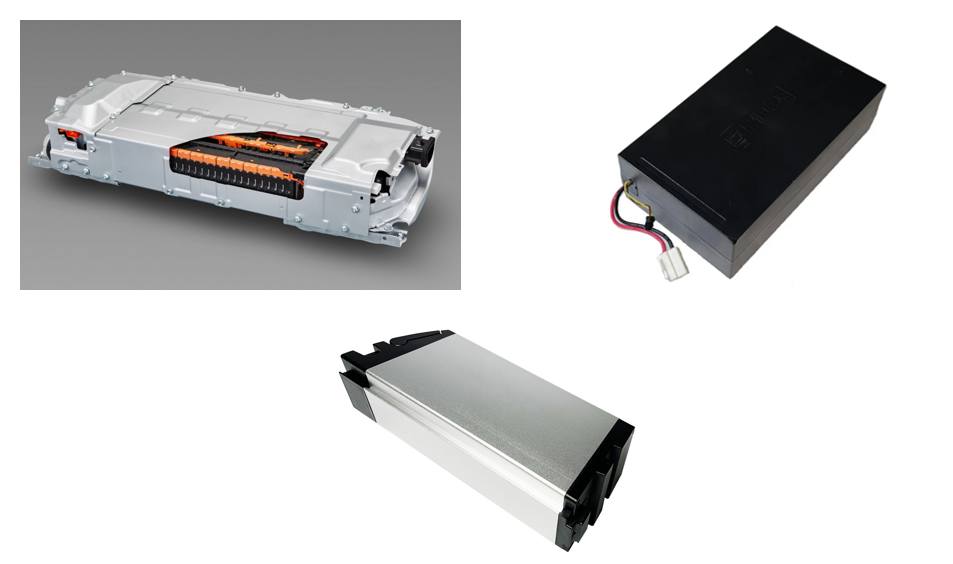

2. Widely Used In Battery Manufacturing Industry

The system is suitable for many types of batteries such as:

- Electric car battery

- Electric motorbike battery

- Electronic device battery

Help businesses meet large production needs and ensure international quality standards.

3. Outstanding Benefits

✔ Outstanding speed: Packing up to 40 cartons/minute , the system ensures high and stable production speed.

✔ Safe and precise: Equipped with 4 or 6 axis robots and safety systems such as protective fences, interlocks, light curtains , ensuring maximum safety for operators.

✔ Optimize labor: Automate the entire process, minimize operating personnel, and save long-term costs.

4. Flexible & Scalable

- Handles a wide range of product sizes: Grippers are customizable for each battery type (vacuum or clamp).

- Flexible program changes: Easy configuration via software, suitable for all new product lines.

- Integrated E-Factory smart software: Monitor operating status, optimize device performance in real time.

5. Commitment From Supplier

- Easy to operate design, quick maintenance

- Fully meet ISO standards and occupational safety requirements

- On-site technical support and flexible warranty policy

- Energy saving solution, optimizing operating costs

6. Main Technical Parameters of Battery Cell Packaging Line

- Industrial Robot: 4 or 6 axis

- Gripper: customized gripper according to product (vacuum or clamp)

- Product feeding conveyor: plastic

- Pallet in/out conveyor

- Control: PLC, HMI

- Frame: Powder coated steel

- Size: customized on request.

- Capacity: 40 cartons/minute

- Product weight: kg/bag

- Pallet Station: Pallet Storage

- Smart monitoring: E-Factory software.

- Safety: Security fence, interlock, Light curtain

The automatic battery cell packaging line is not only a modern production equipment, but also a strategic solution to help businesses improve their competitiveness in the battery industry. With the ability to customize, expand and intelligently integrate, the system is the optimal choice for modern battery factories.