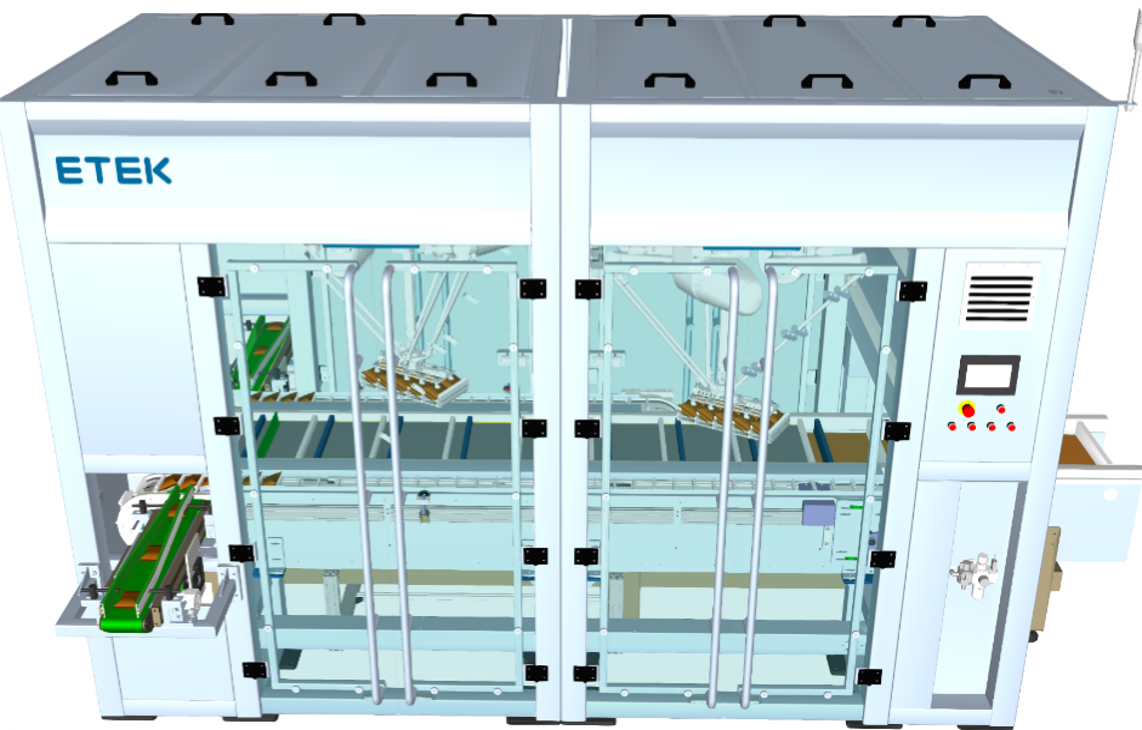

Automatic Cartoning System For Confectionery

Automatic carton packing machine for confectionery, using Delta robot, speed 250 products/minute, 99% automation. Reduce labor, easy to operate, integrated with carton building/gluing, printing – scanning barcodes. Flexible size & packing pattern change. ISO standard, on-site warranty.

- Hotline: 0965 800 166

1. Introduction to automatic cartoning system

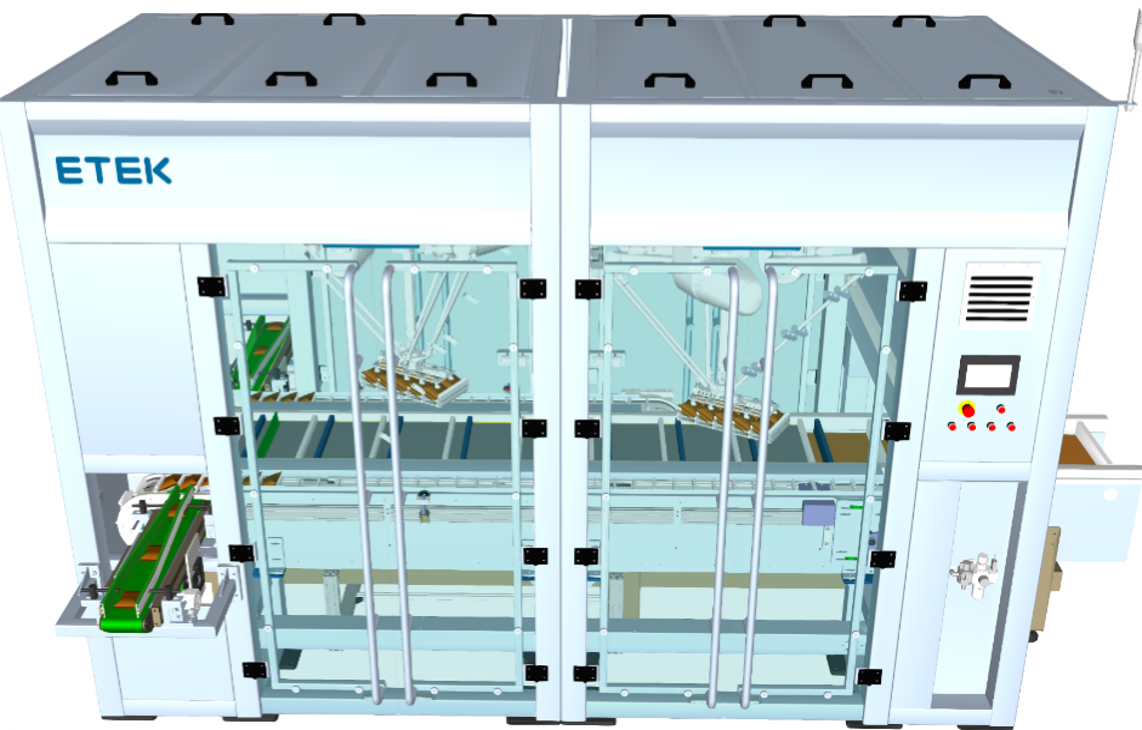

The Automatic Cartoning System for Confectionery is a modern technological solution, specialized in placing products such as confectionery into cartons or trays in order of rows and layers accurately and quickly. The system uses Delta, Scara robots or mechanical structures, meeting diverse production needs in the food and consumer industry.

2. Outstanding applications

Automatic cartoning system is suitable for:

- Confectionery and processed food industry .

- Fast Moving Consumer Goods (FMCG) Industry .

- Product packaging lines require high speed and absolute precision .

3. Benefits of using automatic packing system

- Reduce labor, save long term costs.

- Increased packaging performance – speed up to 250 products/minute .

- Continuous operation in 3 shifts, process automation up to 99% .

- Minimize errors, ensure quality and high accuracy.

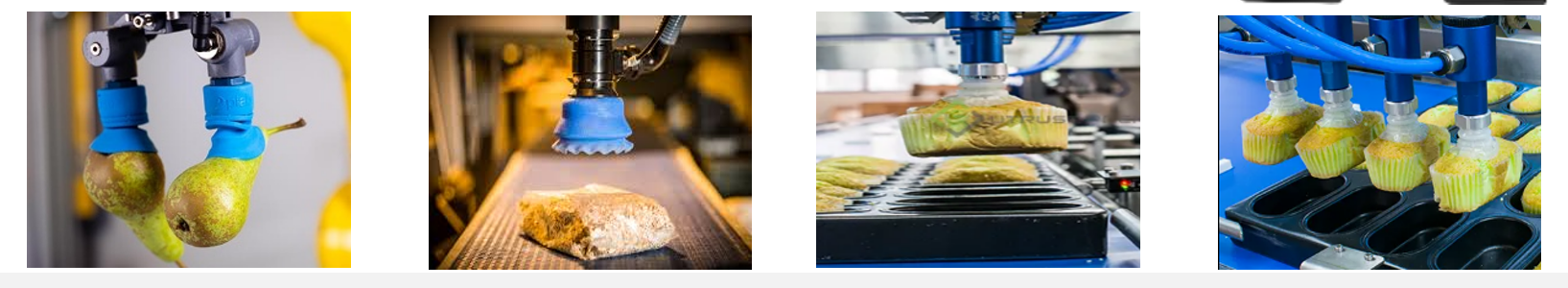

4. Flexibility and scalability

- Easily change the stacking pattern to suit each type of product.

- Support changing product size as required.

- Flexible change of gripper head – meeting many product lines.

- Crate Erector

- Carton Sealer

- Weight Check System

- Barcode Printers & Scanners

5. Commitment from the manufacturer

- User-friendly design , easy to operate and maintain.

- Meets ISO standards , food safety and hygiene .

- On-site technical support , flexible warranty.

- Saves energy , optimizes operating performance.

6. Main technical parameters

- Machine size: 3800 x 1800 x 2200 mm

- Weight: ~1500 kg

- Manufacturing materials: Powder coated steel, Stainless steel

- Power source: 1P – 220V AC, capacity 7kW

- Compressed air requirement: 5 bar, 0.7 m³/min

- Packing speed: 250 products/minute

- Robots used: 2 Delta Robots

- Controller: Customized PLC

- Operation screen: Custom HMI

- Efficiency: 99% (1% NG product)

Are you looking for a modern, economical and effective candy packaging solution ? The Automatic Cartoning System is the perfect choice for your business.